Why is Qualicoat important?

Qualicoat acts as a protective barrier, shielding the surface from these detrimental elements. It helps to prevent corrosion, maintain the structural integrity of the material, and prolong the lifespan of architectural components such as fences, facades, and other aluminium structures.

A high-quality coating for aluminium and its alloys in architectural applications is of utmost importance. Aluminium is a widely used material in the construction industry due to its lightweight, durability, and versatility. However, without a proper coating, aluminium can be susceptible to various environmental factors.

We etch to 2-grams per square meter, which will increase adhesion life and resistant to delimitation, and we only class-2 powder on every single project, which has a much higher chip resistance and longevity benefit.

Moreover, a well-applied coating enhances the aesthetic appeal of aluminium products, providing a smooth and visually pleasing finish. This is particularly important in architectural applications where the appearance of the building or structure plays a significant role.

Benefits of Qualicoat include:

Superior

Quality

Enhanced

Durability

Optimal

Protection

Aesthetic

Appeal

Peace of

Mind

At AliDeck, we take immense pride in the quality and reliability of our products. That is why we subject our aluminium structures to a rigorous testing and proven process to ensure they meet the prestigious standards set by Qualicoat. The Qualicoat system is a renowned quality label organisation dedicated to upholding and promoting the excellence of coating on aluminium and its alloys for architectural applications.

Achieving this coating is a testament to the superior quality and performance of our products. Our aluminium structures, undergo a series of meticulous tests. These tests are designed to evaluate the durability, adhesion, resistance to corrosion, and overall quality of the coating applied to our products.

The 7-Stage Pre-Treatment Process

- 1

Cleaner / Etch: To remove greases, oils & preservatives from the metal surface and etch the metal, in order to produce a clean, oil free surface suitable for treatment.

- 2

First Water Rinse: To remove the majority of the dissolved aluminium, emulsified oil and etch residues without promoting precipitation.

- 3

Second Water Rinse: To remove the remainder of the dissolved aluminium, emulsified oil and etch residues without promoting precipitation.

- 4

Deoxidisation & Conversion: To deoxidise and further etch the surface, subsequently forming an inorganic conversion coating, which will enhance paint adhesion and corrosion resistance.

- 5

Acid Rinse: To remove the acid chemicals from the materials to stop the reaction occurring and etching to carry on.

- 6

Final Water Rinse: To remove any water soluble material and residual conversion coating process from the coated metal prior to painting.

- 7

Deionised Rinse: To remove last remaining water soluble material and residual conversion coating process from the coated metal, leaving a protected surface ready for powder coating.

In-House Powder-Coating for Decking, Cladding, Railings, Balustrades & Balcony Components

We operate an automatic seven-stage pre-treatment powder-coating facility in our warehouse, a game-changing shift in the way we operate. This means that we are able to now control even more of the overall production process, ensuring that project success is built into our range.

With a 95% recovery & recycle booth, we are able to powder-coat all of our aluminium decking boards, soffit cladding, railings, balustrades and balcony component systems to QualiCoat-seaside equivalent standards. A powder-coat finish allows our products to be fire rated to A2-s1, d0 standards which remains well within the current regulations and British Standards.

Qualicoat Seaside standard requires that aluminium be etched to 2 g/m² when using Class 2 powders. We at Alideck meet this standard which ensures that our products maintain the highest quality for a minimum of three decades. We also use class 2 powders across the board on all required products, which provides our customers with the best possible protection against the elements.

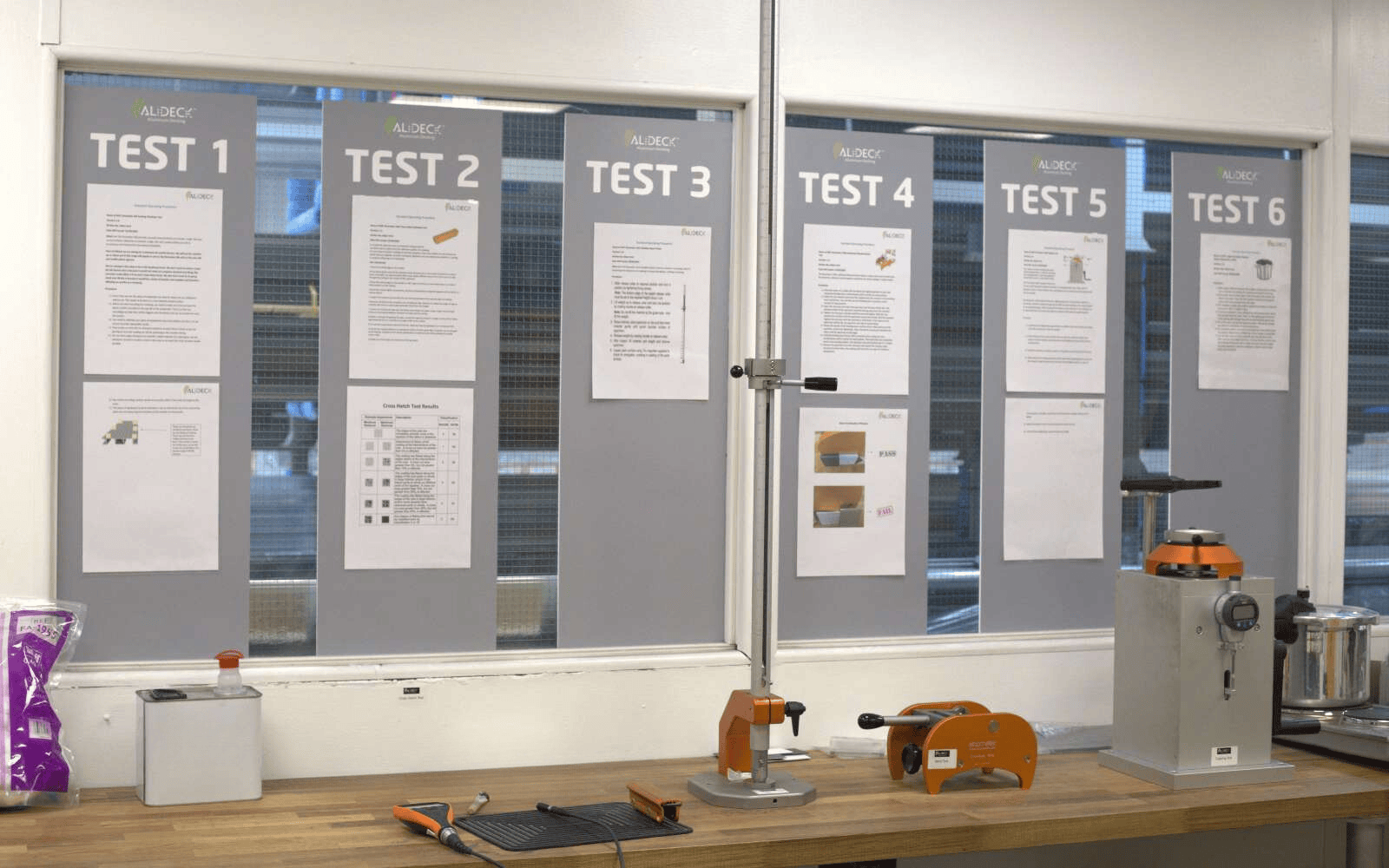

The 6-Stage Testing Process

We also operate a six-stage testing process that enables us to give you a robust 30-year adhesion warranty. Furthermore, our recent Acetic Acid Salt Spray result (accelerated weathering tests) has flown past 3000 hours!

The 6-Stage Process Includes:

- 1

Film Thickness Check: Using an Elcometer we will check the thickness of the coating, making sure it’s between 60 and 80 microns. To conform to A2-s2, d0, and A2fl-s1 fire certifications

- 2

Cross Hatch Test: Conducted using pressure-sensitive tape after cross-hatching process to verify perfect adhesion and durability, even under stress.

- 3

Impact Test: Conducted by dropping a vertically sliding weight to test the impact resistance of our coating.

- 4

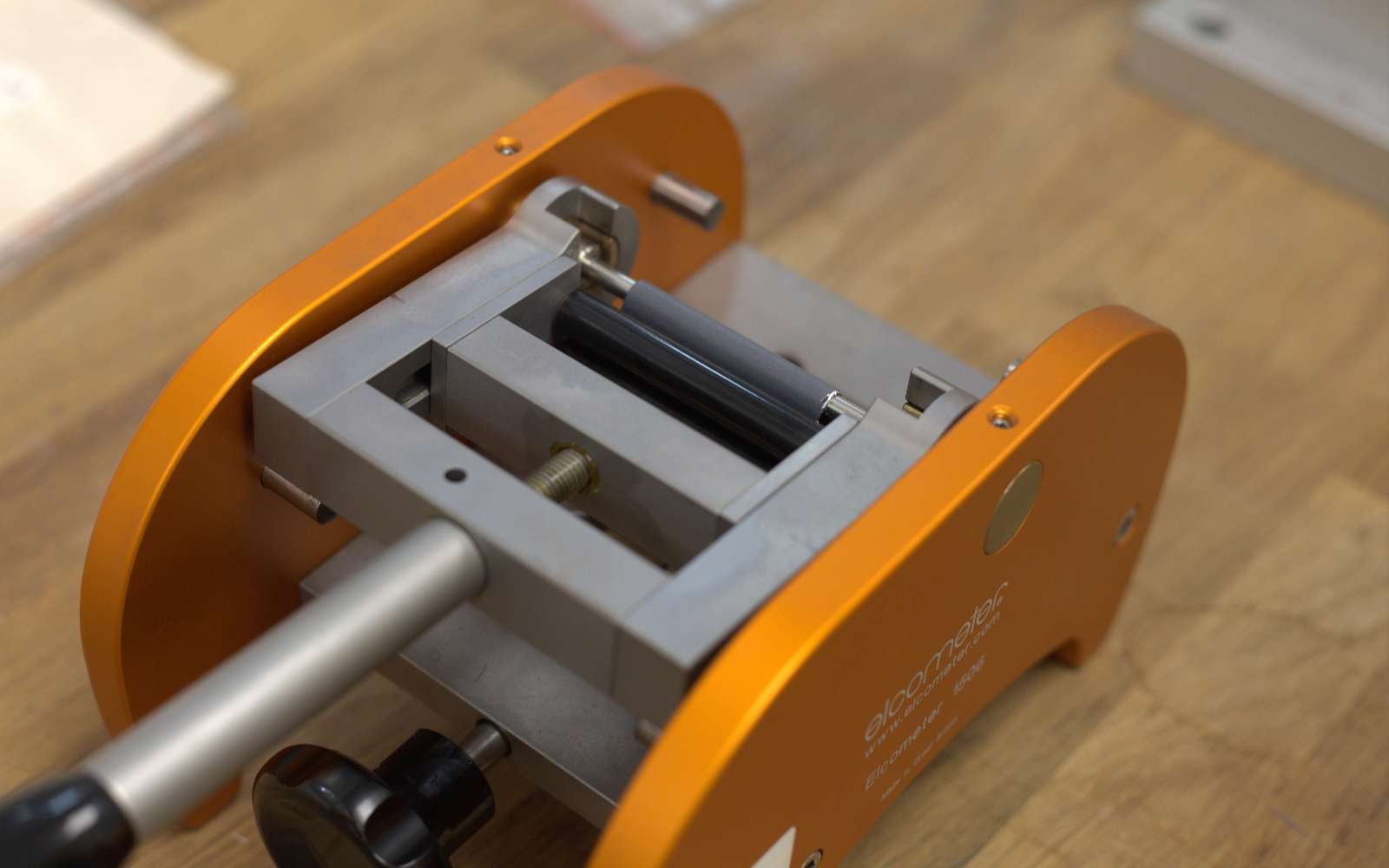

Bend Test: Placing our test panel inside the Mandrel, it is then folded to test the coating adhesion quality under the bending forces of folding.

- 5

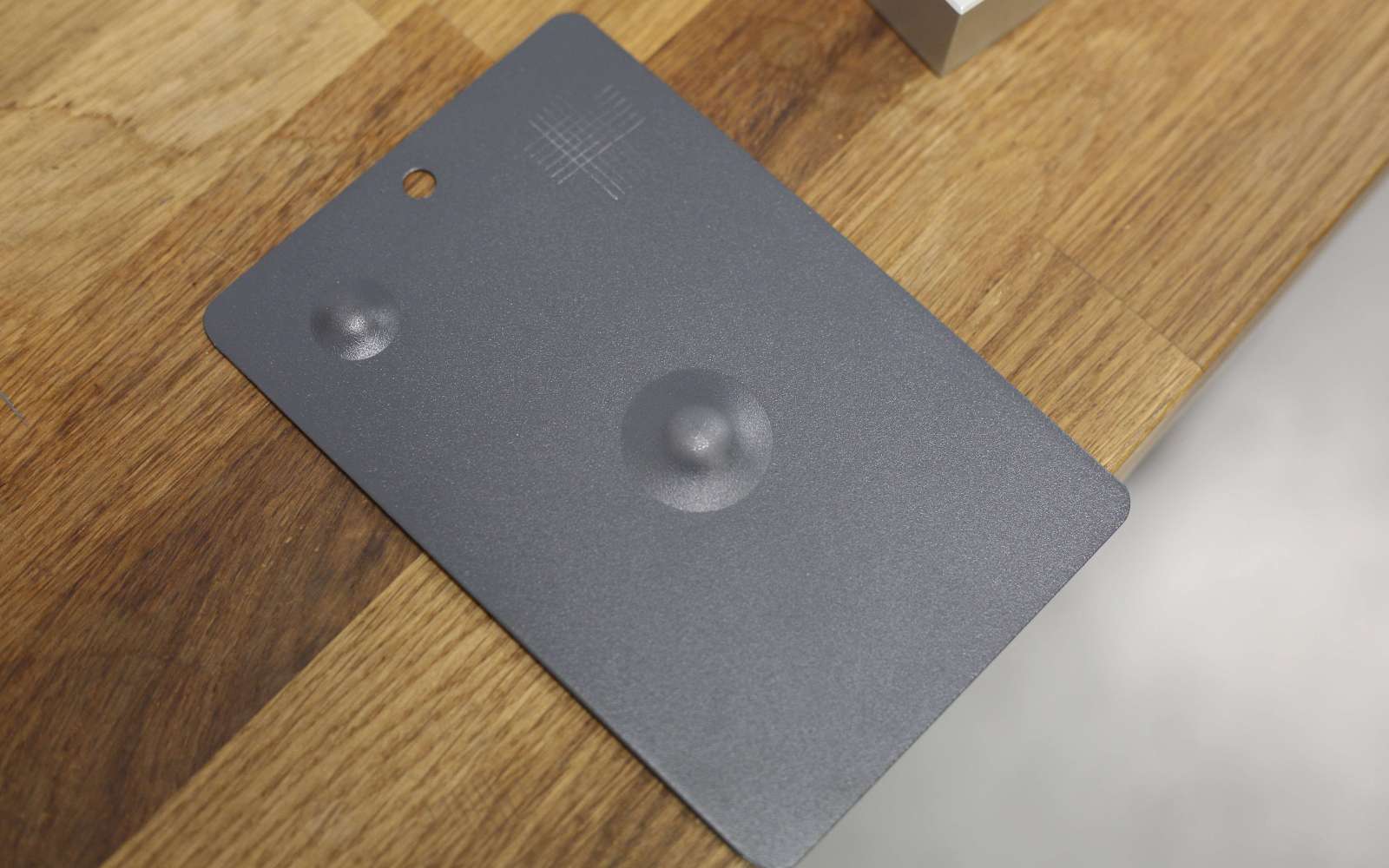

Cupping Test: Similar to the impact test, but this time we slowly wind down and progressively punch into the test panel, to a 5mm indentation.

- 6

Accelerated Weathering Test: For an hour under pressure, we cook the test panel to ensure we do not get any blistering on the coating at which point we repeat the cross-hatch test. This simulates over a decade of elemental exposure, verifying endurance

Maintenance of Qualicoat products

To ensure the longevity and optimal performance of products finished with the Qualicoat system, it is important to follow proper maintenance and care practices. Here are some guidelines to help you maintain the beauty and functionality of your Qualicoat assured products:

For more information on installation and maintenance of AliDeck’s products, please use the button below:

Here’s what the Managing Director at Extreme Balconies had to say after the tour at our factory recently

“The hospitality provided by AliDeck is consistently outstanding, and the excellence of your staff shines through in their exceptional support and ongoing innovation. The facility itself is remarkable, yet it’s the quality of the product that truly captures attention.

With a magnificent on-site powder-coating facility and the use of Qualicoat 2 as a standard, offering a 30-year warranty, AliDeck’s products distinguish themselves from competitors. It’s a privilege to work with you.”

- Damien – Managing Director, Extreme Balconies

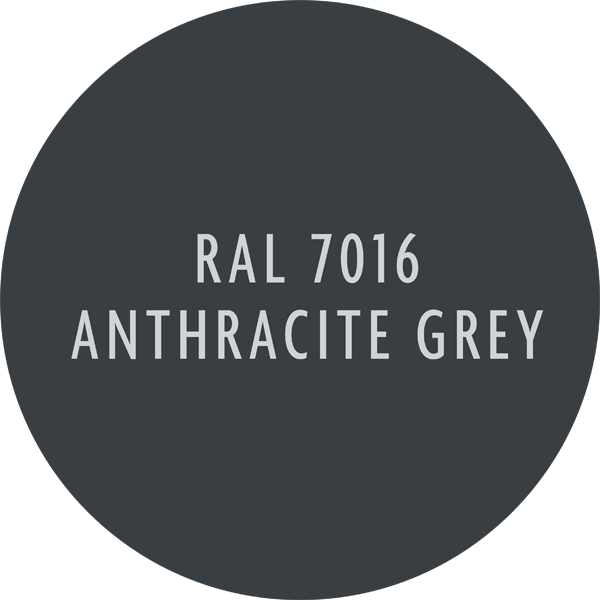

Standard Powder-coating Colours

We offer 10 colours as standard, with the option to match bespoke requests of any colour at an additional cost. We offer class 2 which brings a rougher texture to provide a grippier finish. It is worth noting, however, that our class 2 texture is not available on our balustrade systems.

Qualicoat is a quality label organisation committed to maintaining and promoting the quality of coating on aluminium and its alloys for architectural applications!

See below for how we meet the qualicoat standards

BS 6496:1984: Specification for powder organic coatings for application and stoving to aluminium alloy extrusions, sheet and preformed sections for external architectural purposes, and for the finish on aluminium alloy extrusions. Alideck extrusions are finished using the following EN standards:

EN 12206-1:2004: Paints and varnishes. Coating of aluminium and aluminium alloys for architectural purposes. Coatings prepared from coating powder

EN ISO 2409:2013: Paints and Varnishes, Cross Cut Test. Our quality department also perform the following tests on our powder coated profiles.

Oven curing temperatures are checked and recorded daily. To obtain the requirements for different powders we calculate these using the powder suppliers data sheets.

ISO9227: Acetic Acid Salt Spray Test

EN ISO 3231: Resistance to humid atmospheres containing Sulphur Dioxide

EN ISO 11341: Accelerated weathering test

EN ISO 2810: Natural weathering test (Florida Test). (Carried out on Powder type)

EN ISO 12206-1: Resistance to mortar (Carried out on Powder type)

EN ISO 6270-2: Constant Climate Condensation Water test Our aluminium is sent through a variety of pre-treatment chemical baths that remove a very fine layer off the surface before powder coating.

QUALICOAT 2.1: Visual inspection at 3 metres for internal and 5 metres for external extrusions (Our Inspectors visually inspect at 1 metre as standard)

QUALICOAT 2.2: Gloss level check to within 5% +/- of the AliDeck’s stated level. [EN ISO 2813]

QUALICOAT 2.3: Thickness checks to see that the material is coated with at least 60 microns of powder, average. [EN ISO 2360]

QUALICOAT 2.4.1: Cross Hatch cuts are made at 2mm spacing with one being at 90° to the other cut, tape is then applied, left for 2 minutes and removed to check for adhesion of paint. [EN ISO 2409 2013]

QUALICOAT 2.6: Cupping test is carried out to check for adhesion with the substrate [EN ISO 1520]

QUALICOAT 2.7: Bend test on a 5mm Mandrel to ensure adhesion after bending [EN ISO 1519]

QUALICOAT 2.8: Impact test with an energy of 2.5Nm to ensure that the coating adheres to the substrate [EN ISO 6272 / ASTM D2794]

QUALICOAT 2.11: Machu test (Accelerated corrosion test) in a solution made up of Sodium Chloride, Acetic Acid and Hydrogen Peroxide at 37°C. Duration 48 hours

QUALICOAT 2.14: Polymerisation test (Wipe with MEK for 30 seconds)

QUALICOAT 2.16: Resistance to boiling water in a pressure cooker. Duration 1 hour 100Kpa

QUALICOAT 2.18: Sawing and drilling to ensure that there is no flaking after cutting (using sharp tools)