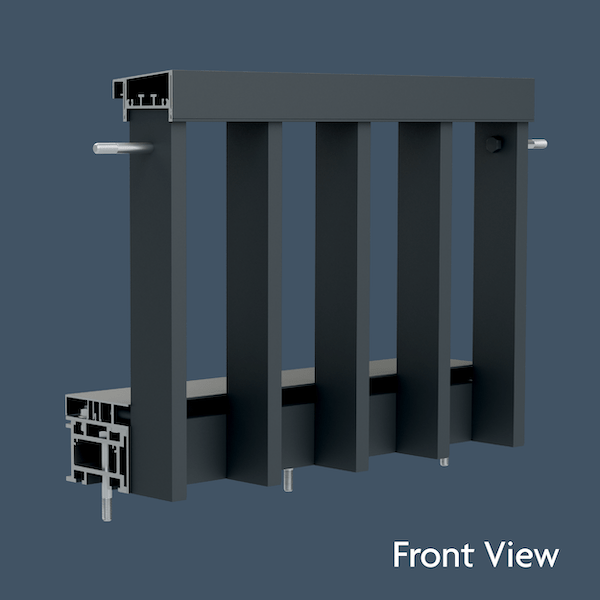

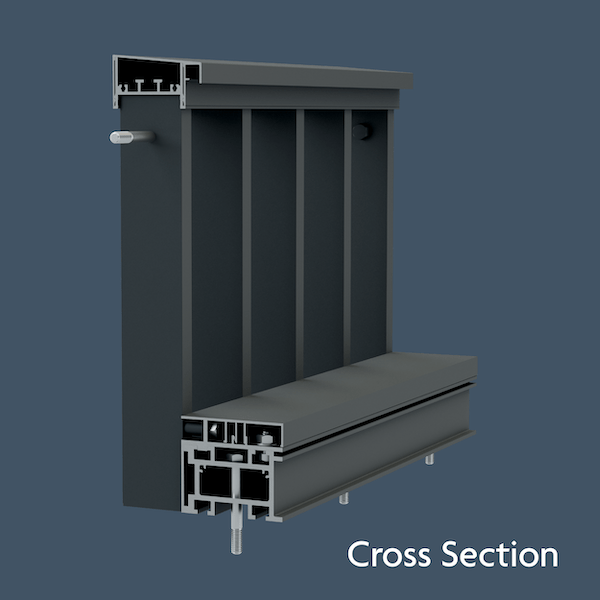

Inner-Mounted Option Specification

- Fire resistant: A2-s1, d0

- Coating thickness – 60-80 microns

- Coating Impact test – with an energy of 2.5Km to ensure that the coating adheres to the substrate to EN ISO 6272 / ASTM D2794

- Bend test – on 5mm mandrel to ensure adhesion after bending to EN ISO 1519

- Machu Test (accelerated corrosion test) in a solution made up of sodium chloride cetic acid and hydrogen peroxide at 37 degrees C Duration 48 hours

- Qualicoat 2.4.1. – cross hatch cuts are made at 2mm spacings with one being at 90 degrees to the other cut, tape is the applied left for 2 minutes and removed to check for adhesion of paint (EN ISO 2409 2013)

- Qualicoat 2.18 – sawing and drilling test to ensure no flaking after cutting (using sharp tools)

- Acid salt spray test – ISO 9227

- EN ISO 3231 – Resistance to humid atmospheres containing Sulphur Dioxide

- EN ISO 11341 – Accelerated weathering test

- EN ISO 20810 – Natural weathering test (Florida Test) (Carried out on Powder Type)

- EN ISO 12206-1 – Resistance to mortar (Carried out on powder type)

- EN ISO 6270 – 2 – Constant climate condensation water test

- Choice of colours – Available in a wide range of RAL colours

- Contemporary aluminium metal balustrade system.

Please note: Test result data is indicative only. Loading performance and ensuring the AliRail system integrates with specific balcony designs is the responsibility of the balcony designer. AliDeck has not performed any project-specific calculations, so the designer’s calculations must account for all relevant components.