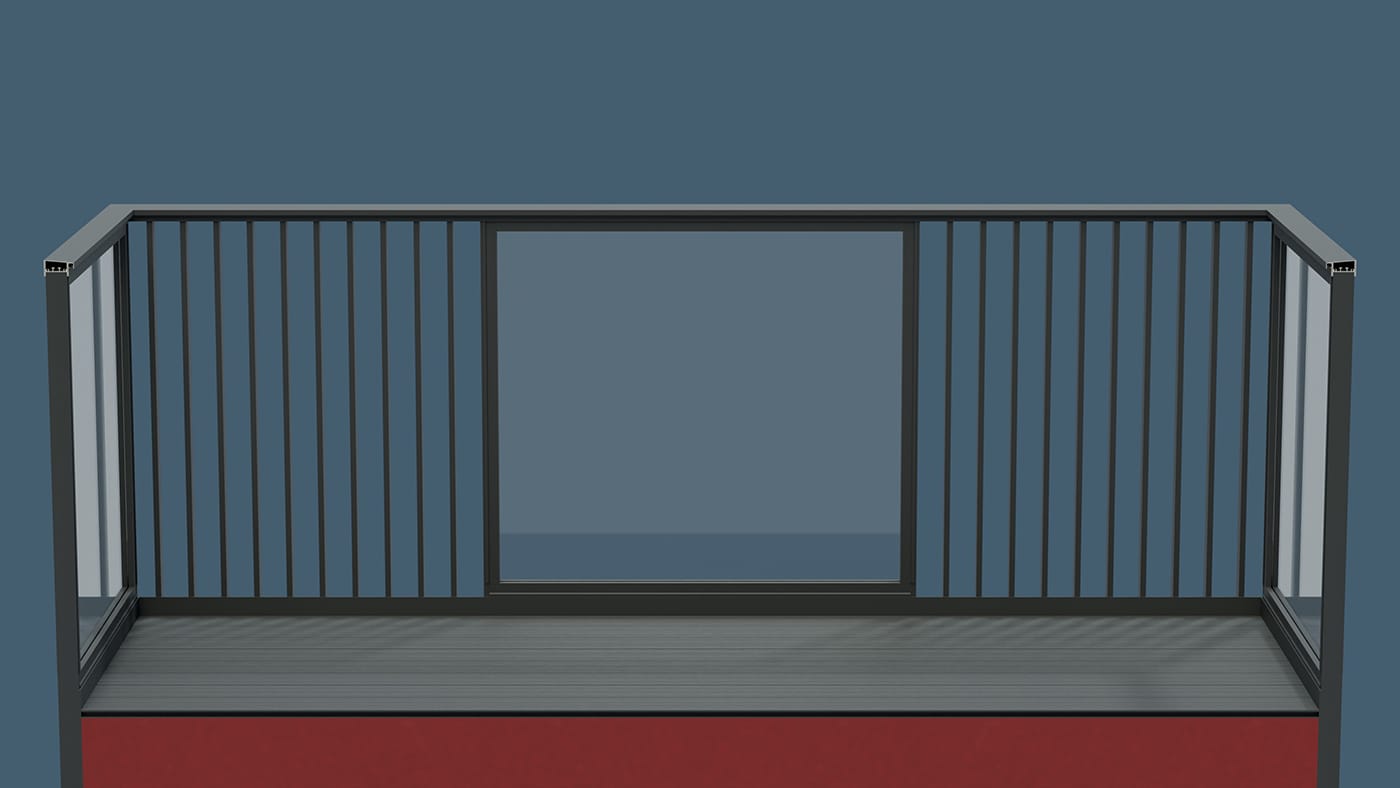

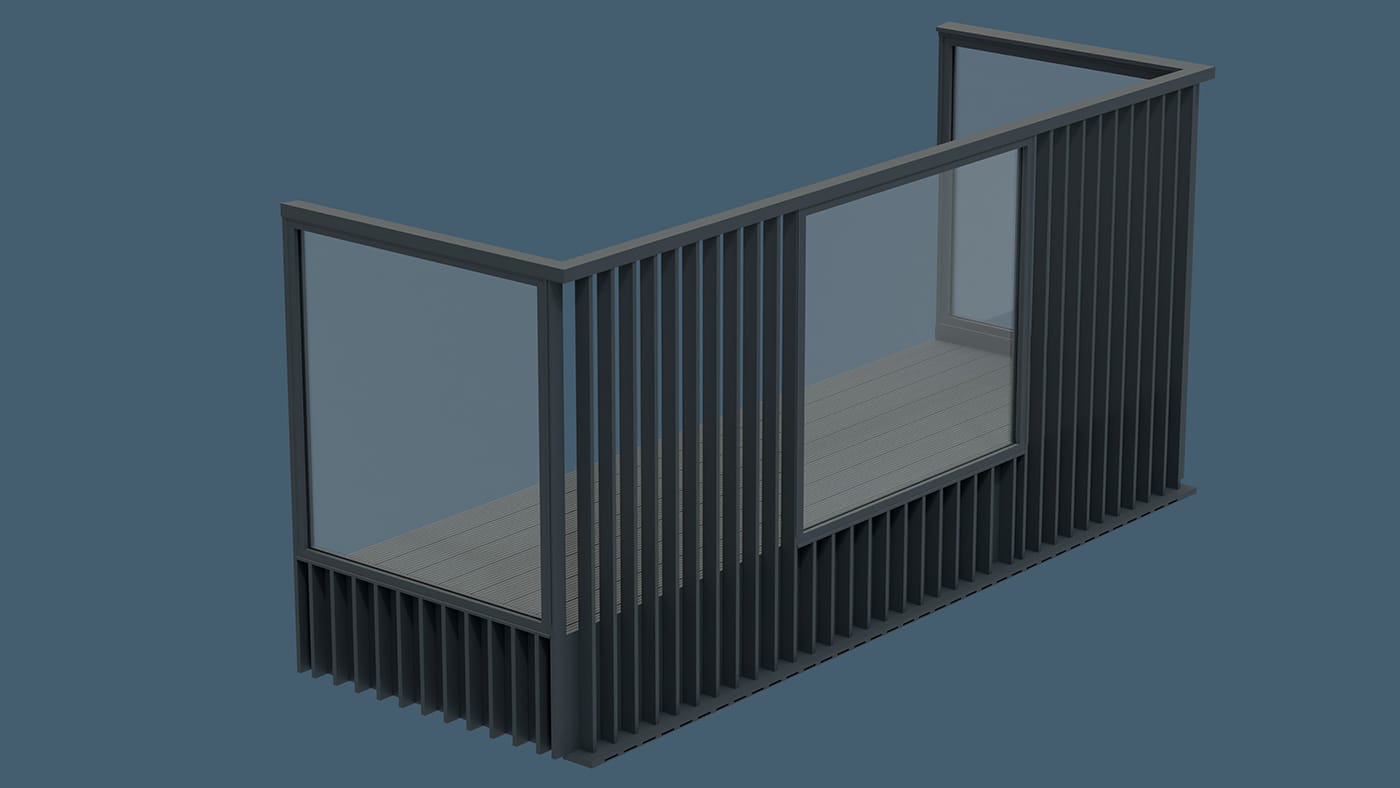

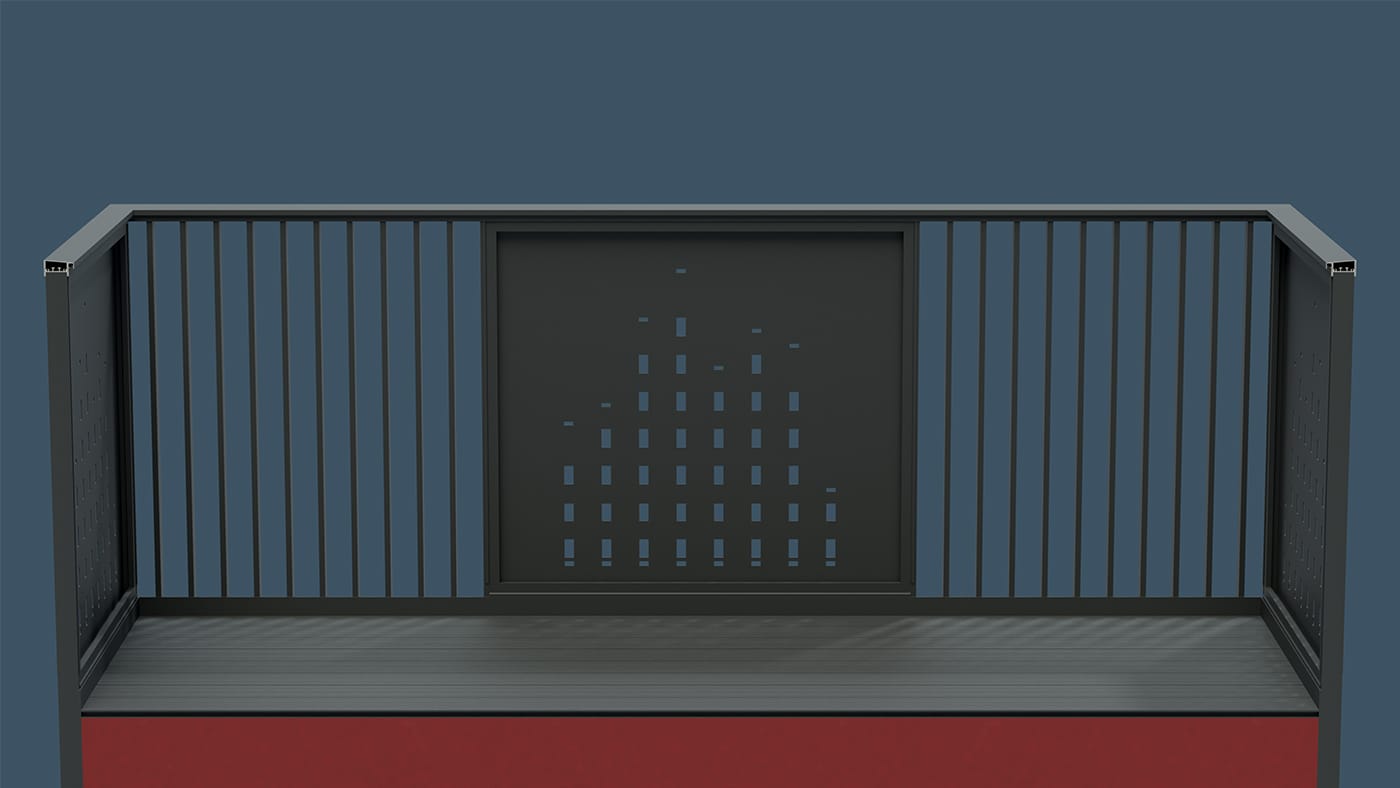

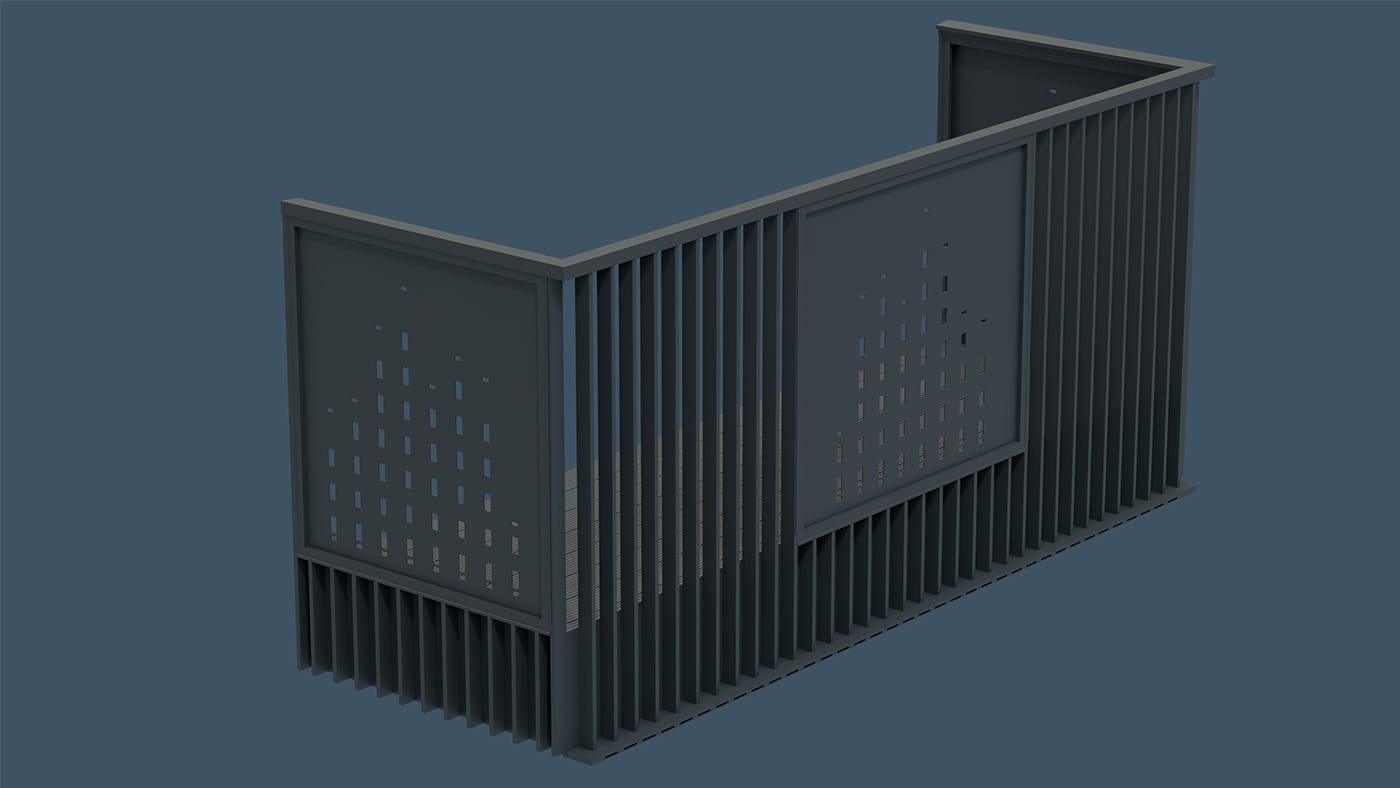

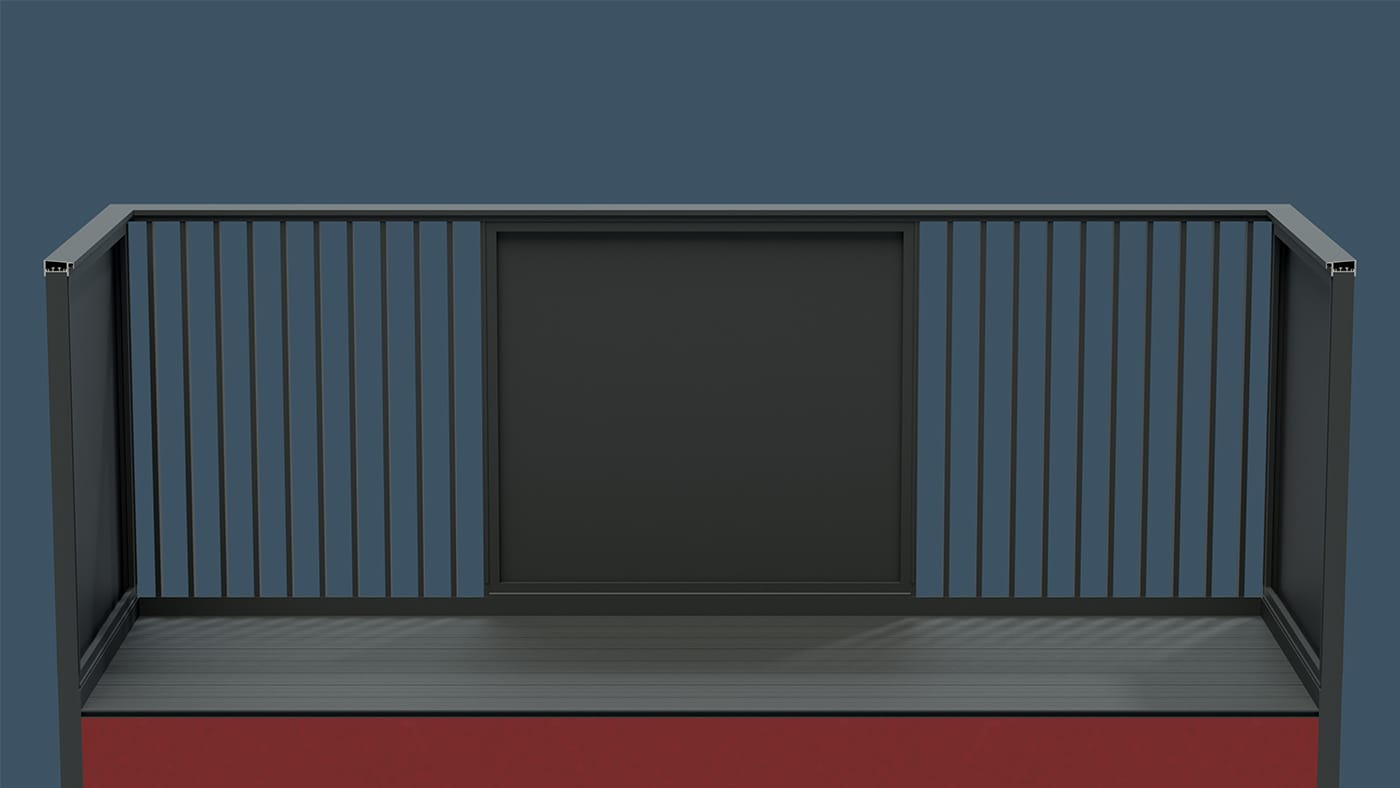

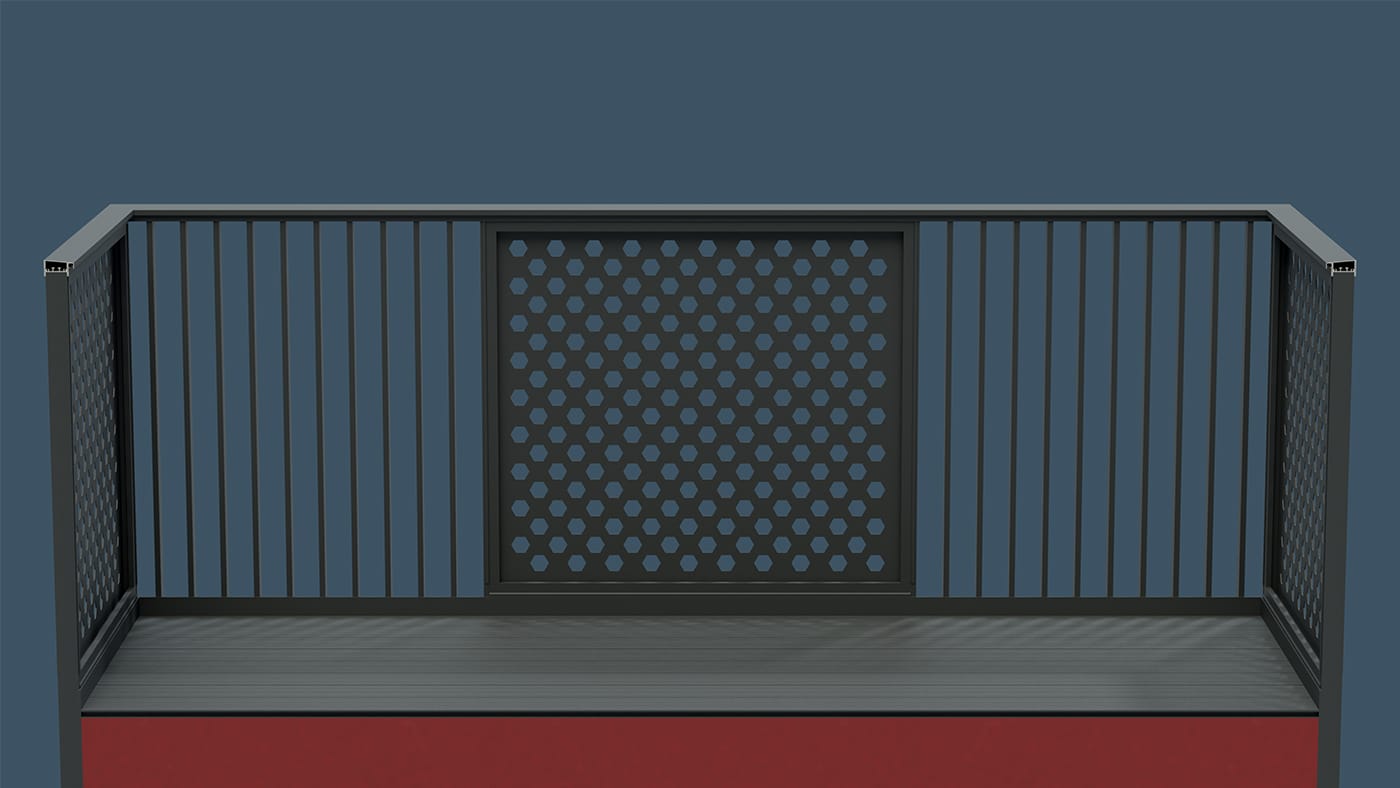

AliRail Vertical Infill Spindle Balustrade System

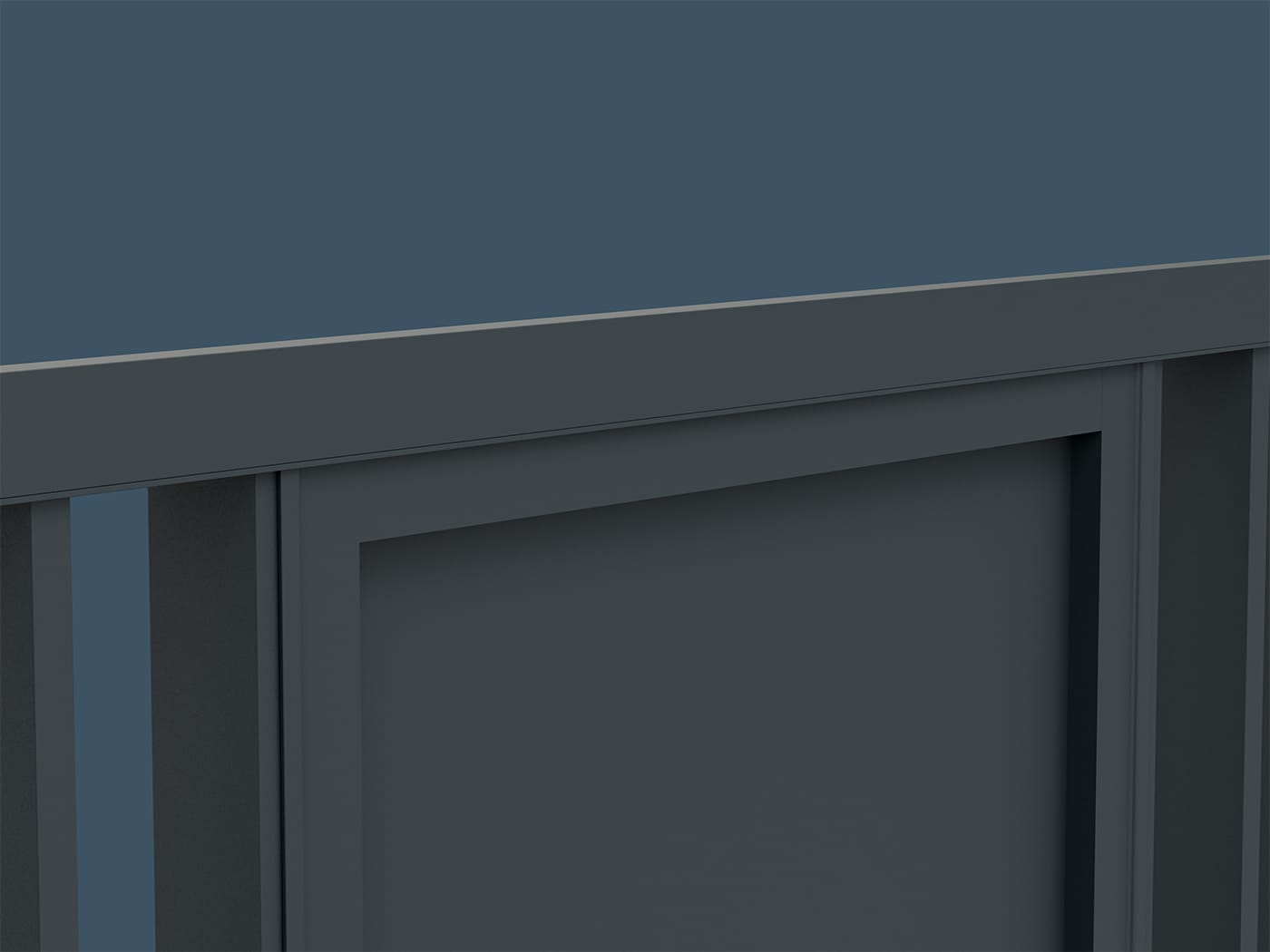

The AliRail aluminium balustrade system is a complete solution for all balustrade and rail requirements on steel cantilever and concrete inset balconies. Consisting of extruded aluminium components for high strength and low weight, AliRail’s kit-form construction provides excellent versatility and a solution for all requirements.

Two Fixing Options To Suit Your Loading Requirements

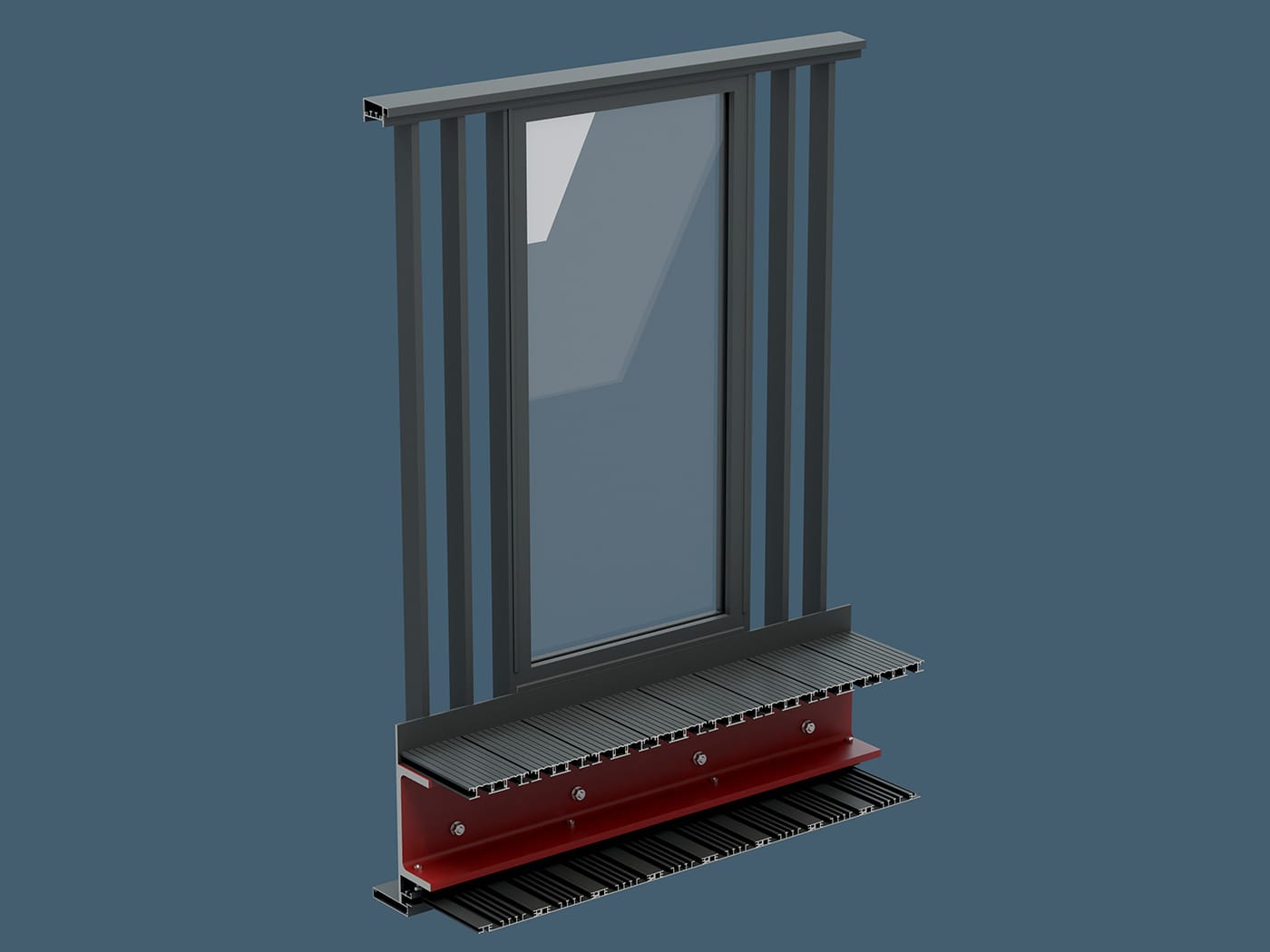

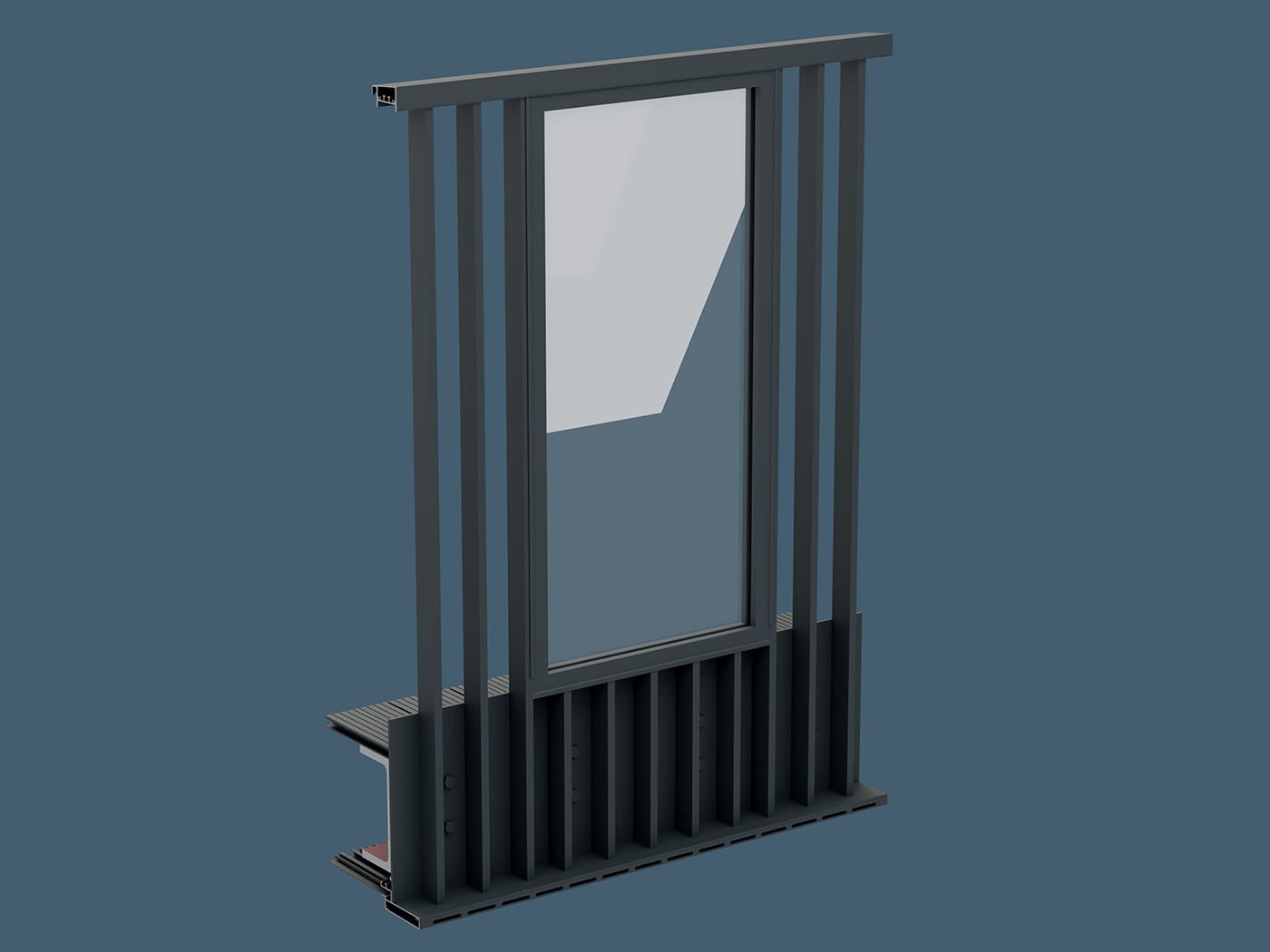

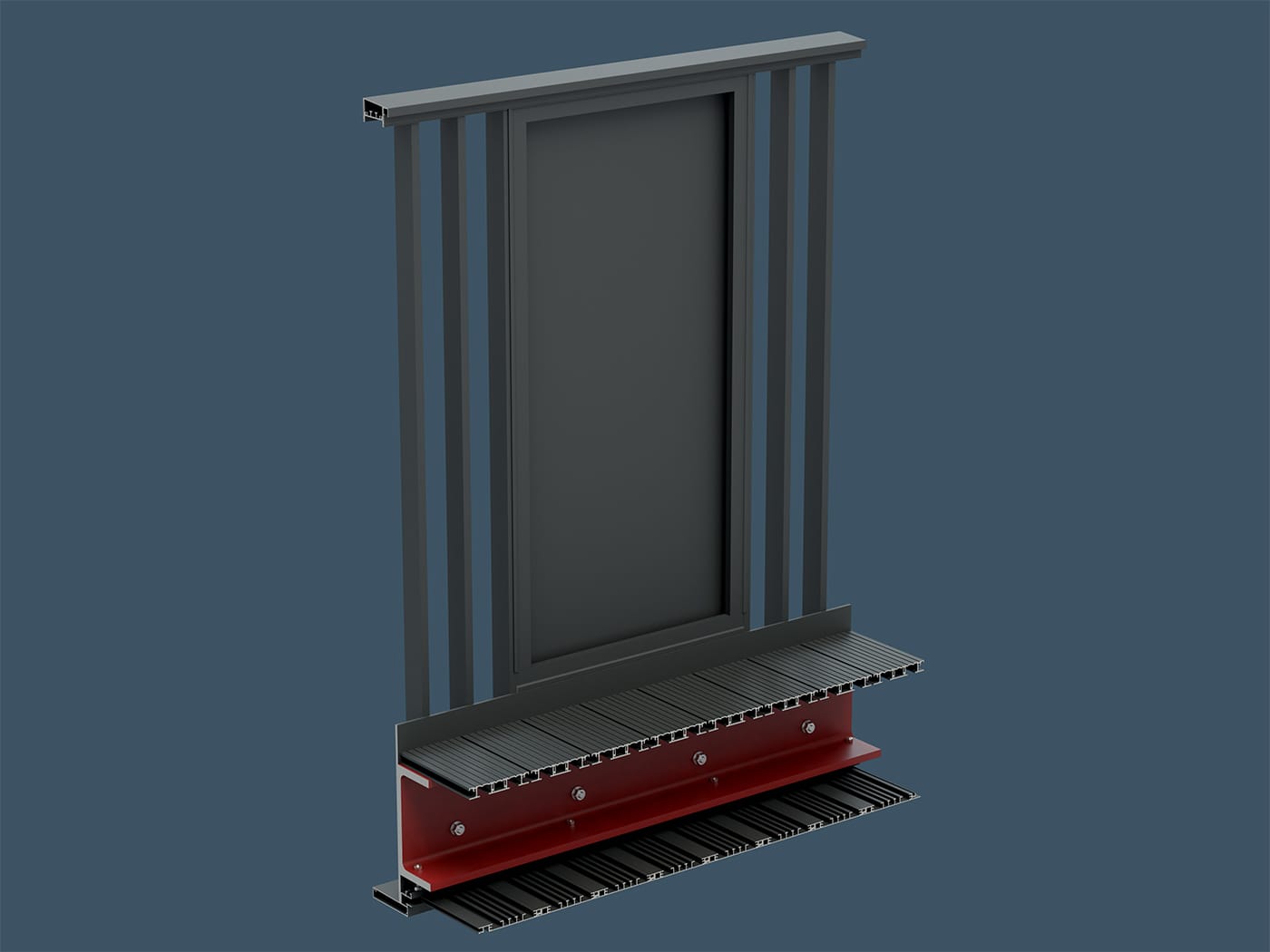

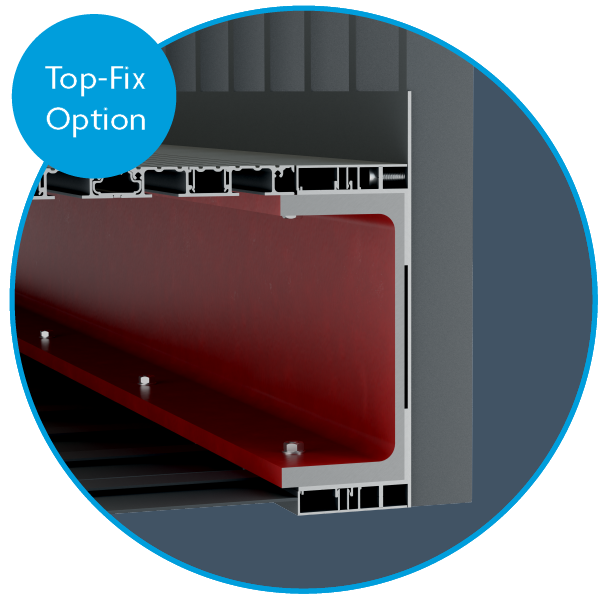

Simple Installation Steps From Top or Plate-Fix Options

Plate-Fix Specification

The AliRail Vertical Infill Plate-Fix Option is load tested in accordance with BS 6180:2011 (0.74kN/m horizontal line load, 0.5kN infill point load, 1.0kN/m2 infill distributed load).

- Fire resistant: A2-s1, d0

- Loading performance:

- Horizontal line load: 0.74kN/m

- Infill point load: 0.5kN/m

- Infill distributed load: 1.0kN/m2

- Coating thickness – 60-80 microns

- Impact test – with an energy of 2.5Km to ensure that the coating adheres to the substrate to EN ISO 6272 / ASTM D2794

- Bend test – on 5mm mandrel to ensure adhesion after bending to EN ISO 1519

Machu Test (accelerated corrosion test) – in a solution made up of sodium chloride acetic acid and hydrogen peroxide at 37 degrees C Duration 48 hours - Qualicoat 2.4.1. – cross hatch cuts are made at 2mm spacings with one being at 90 degrees to the other cut, tape is the applied left for 2 minutes and removed to check for adhesion of paint (EN ISO 2409 2013)

- Qualicoat 2.18 – sawing and drilling test to ensure no flaking after cutting (using sharp tools)

- Acid salt spray test – ISO 9227

- EN ISO 3231 – Resistance to humid atmospheres containing Sulphur Dioxide

- EN ISO 11341 – Accelerated weathering test

- EN ISO 20810 – Natural weathering test (Florida Test) (Carried out on Powder Type)

- EN ISO 12206-1 – Resistance to mortar (Carried out on powder type)

- EN ISO 6270 – 2 – Constant climate condensation water test.

- Choice of colours – Available in a wide range of RAL colours.

Top-Fix Specification

The AliRail Vertical Infill Top-Fix Option is load tested in accordance with BS 6180:2011 (1.5kN/m horizontal line load, 1.5kN infill point load, 1.5kN/m2 infill distributed load)..

- Fire resistant: A2-s1, d0

- Loading performance:

- Horizontal line load: 1.5kN/m

- Infill point load: 1.5kN/m

- Infill distributed load: 1.5kN/m2

- Coating thickness – 60-80 microns

- Impact test – with an energy of 2.5Km to ensure that the coating adheres to the substrate to EN ISO 6272 / ASTM D2794

- Bend test – on 5mm mandrel to ensure adhesion after bending to EN ISO 1519

- Machu Test (accelerated corrosion test) – in a solution made up of sodium chloride acetic acid and hydrogen peroxide at

37 degrees C Duration 48 hours - Qualicoat 2.4.1. – cross hatch cuts are made at 2mm spacings with one being at 90 degrees to the other cut, tape is the applied

left for 2 minutes and removed to check

for adhesion of paint (EN ISO 2409 2013) - Qualicoat 2.18 – sawing and drilling test to ensure no flaking after cutting (using sharp tools)

- Acid salt spray test – ISO 9227 EN ISO 3231 – Resistance to humid

atmospheres containing Sulphur Dioxide - EN ISO 11341 – Accelerated weathering test

- EN ISO 20810 – Natural weathering test (Florida Test) (Carried out on Powder Type) EN ISO 12206-1 – Resistance to mortar (Carried out on powder type)

- EN ISO 6270 – 2 – Constant climate condensation water test.

- Choice of colours – Available in a wide range of RAL colours.

The AliRail Vertical Infill Spindle Balustrade System is designed for easy installation and is supplied in pre-fabricated elevations. Full installation guides are available on www.alideck.co.uk.

AliRail is constructed completely from 100% aluminium (6063 T6 grade), up to 67% of which has been recycled to make this system eco-friendly and much better for the environment.

The AliRail Vertical Infill Spindle Balustrade System has been subjected to independent testing for load performance. The Plate Fix option achieved 0.74kn/m loading while the Top-Fix option achieved 1.5kn/m. Test result data is indicative only and loading performance for individual balcony designs is the responsibility of the balcony designer.

Due to the fact that AliRail is aluminium and finished using the 5 stage Qualicoat system, little or no maintenance is required. General grime can be removed simply with a damp, lint free cloth or mop with warm soapy water

AliRail is coloured using the Qualicoat powder coating finish. Qualicoat is a quality label organisation committed to maintaining and promoting the quality of coating on aluminium and its alloys for architectural applications.

AliRail is supplied with a 30 year warranty against splitting, cracking, warping, splintering, rotting, twisting and material or manufacturing defects. It has a minimum 60 year life expectancy.

AliRail is available in our full range of standard colours. Please refer to our Standard Colour Range datasheet for colour options (available at www.alideck.co.uk/downloads). Non-standard colours are available on request as special orders, but may affect cost and lead-time.

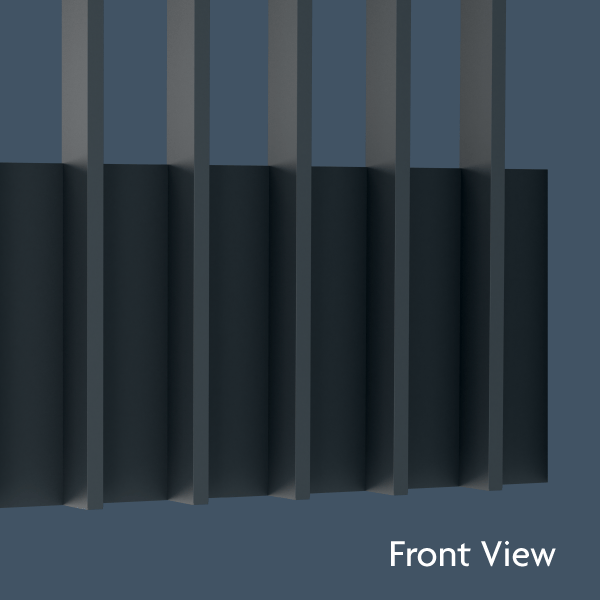

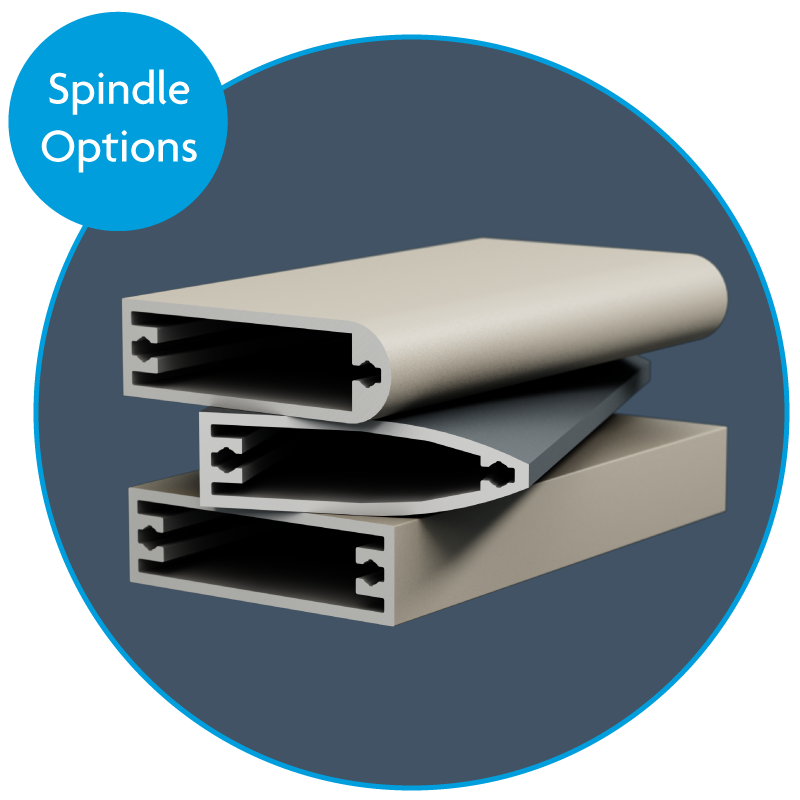

AliRail Vertical Infill Spindles & Panels

The AliRail aluminium balustrade system is a complete solution for all balustrade and rail requirements on steel cantilever and concrete inset balconies. Consisting of extruded aluminium components for high strength and low weight, AliRail’s kit-form construction provides excellent versatility and a solution for all requirements.

Our Vertical Infill Spindle Balustrade is our classic balcony balustrade, specifically designed to provide a viable alternative to steel balustrades. With multiple spindle options available, designers are provided with a range of choices to achieve sleek, modern balcony balustrades.

Technical Downloads

Top-Fix Datasheet

Download DatasheetDatasheet

Plate-Fix Datasheet

Download DatasheetDatasheet

TOP & PLATE-FIX CAD PDF

Download PDFCAD PDF

AliRail Vertical Infill in NBS Source

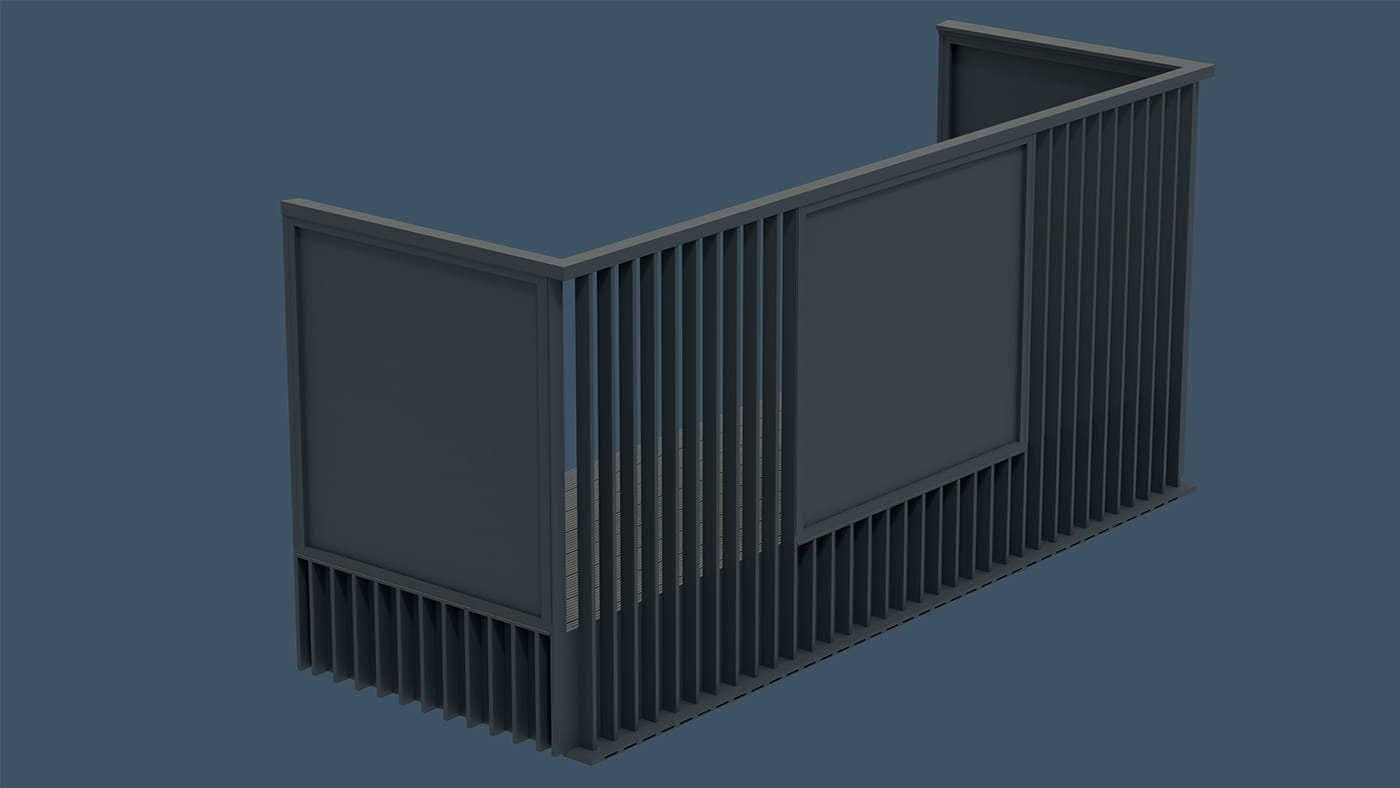

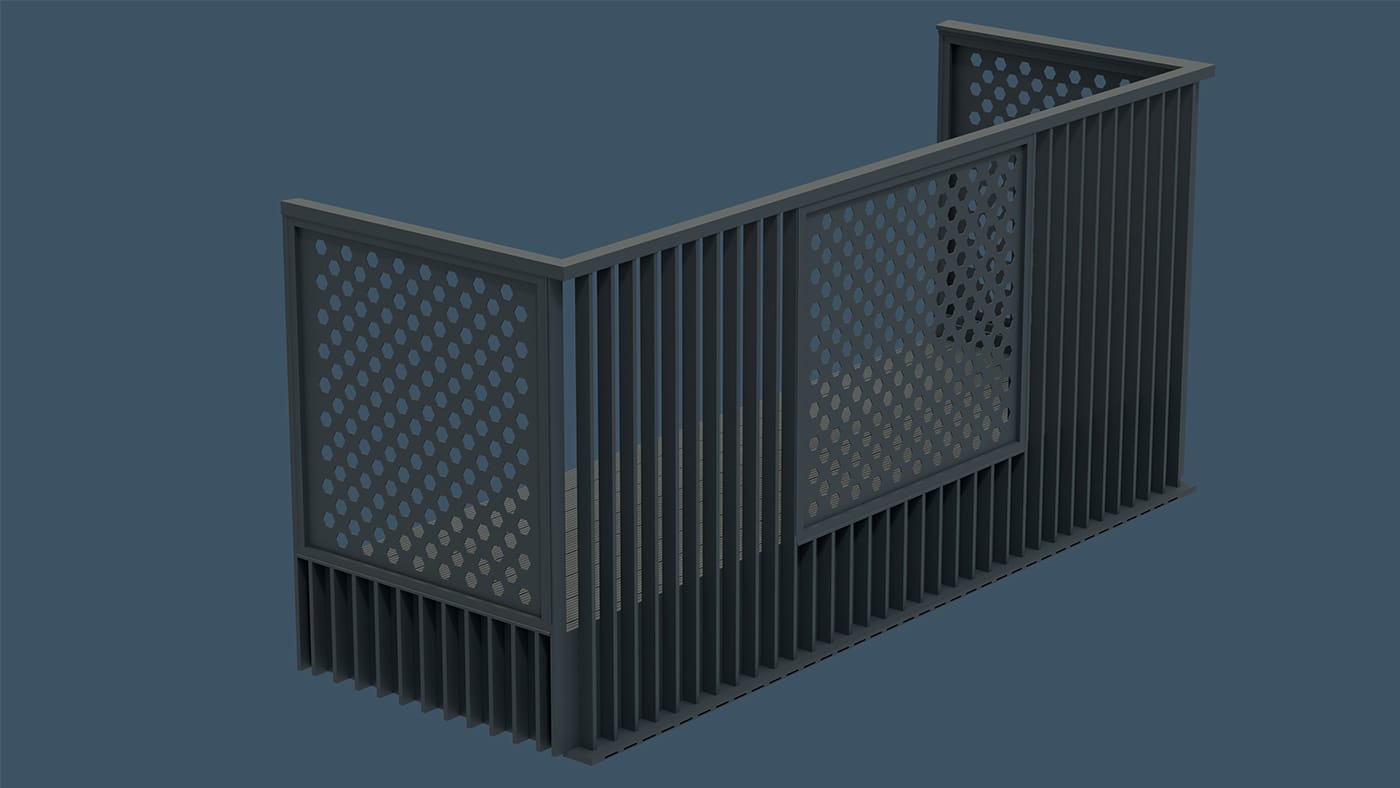

Versatile Installation Options

For steel cantilever balconies, the AliRail Vertical Infill Spindle Balustrade is available in two fixing options; Plate or Top-Fix. The subtle differences between these fixing-to-steel methods allow for accommodation of the widest range of balcony designs.

Supplied in kit-form, balustrade elevations are bespoke manufactured by AliDeck to client specification and can be shipped in balcony-specific despatch for excellent operational efficiencies on-site. With balustrade elevations simply fixed to steel framework, installation is quickly completed with rail corner internal connections and fitting of the handrail cover.