Reducing Construction Delays with Modular and Time-Saving Systems

For developers and contractors, construction delays remain a persistent challenge, leading to higher costs, project overruns, and frustrated stakeholders. Delays caused by labour shortages, unpredictable weather, and supply chain disruptions can significantly impact timelines, making efficiency and reliability critical priorities.

To address these issues, many in the construction industry are turning to modular systems. By providing complete solutions—including decking, drainage, cladding, balustrades, and fencing—aluminium systems help streamline processes and keep projects on schedule. Manufactured in the UK, these systems not only offer precision-engineered quality but also ensure supply chain reliability, further reducing delays and risks.

Time-Saving Benefits of Modular Construction

The appeal of modular construction lies in its ability to simplify and accelerate workflows. Unlike traditional construction methods, which often involve a complex sequence of trades and lengthy on-site work, modular systems are prefabricated off-site in controlled environments. These pre-engineered components are then delivered ready to assemble, saving significant time.

For instance, while foundational work takes place on-site, components such as aluminium decking, cladding, or drainage systems can be manufactured simultaneously off-site. This parallel approach minimises downtime and allows for faster project progression.

Weather, often an uncontrollable factor in the UK, is also less likely to cause delays with modular systems. Since the bulk of manufacturing is done off-site, installations are quicker and less dependent on favourable conditions, giving contractors a more predictable timeline.

Complete Balcony Solutions

One of the most effective applications of modular systems is in the delivery of complete balcony solutions, encompassing aluminium decking, drainage systems, cladding, balustrades, and fencing. Traditional balcony construction often involves coordinating multiple trades, which can create bottlenecks and slow down progress. Modular systems address these challenges by offering integrated solutions that are faster and easier to install.

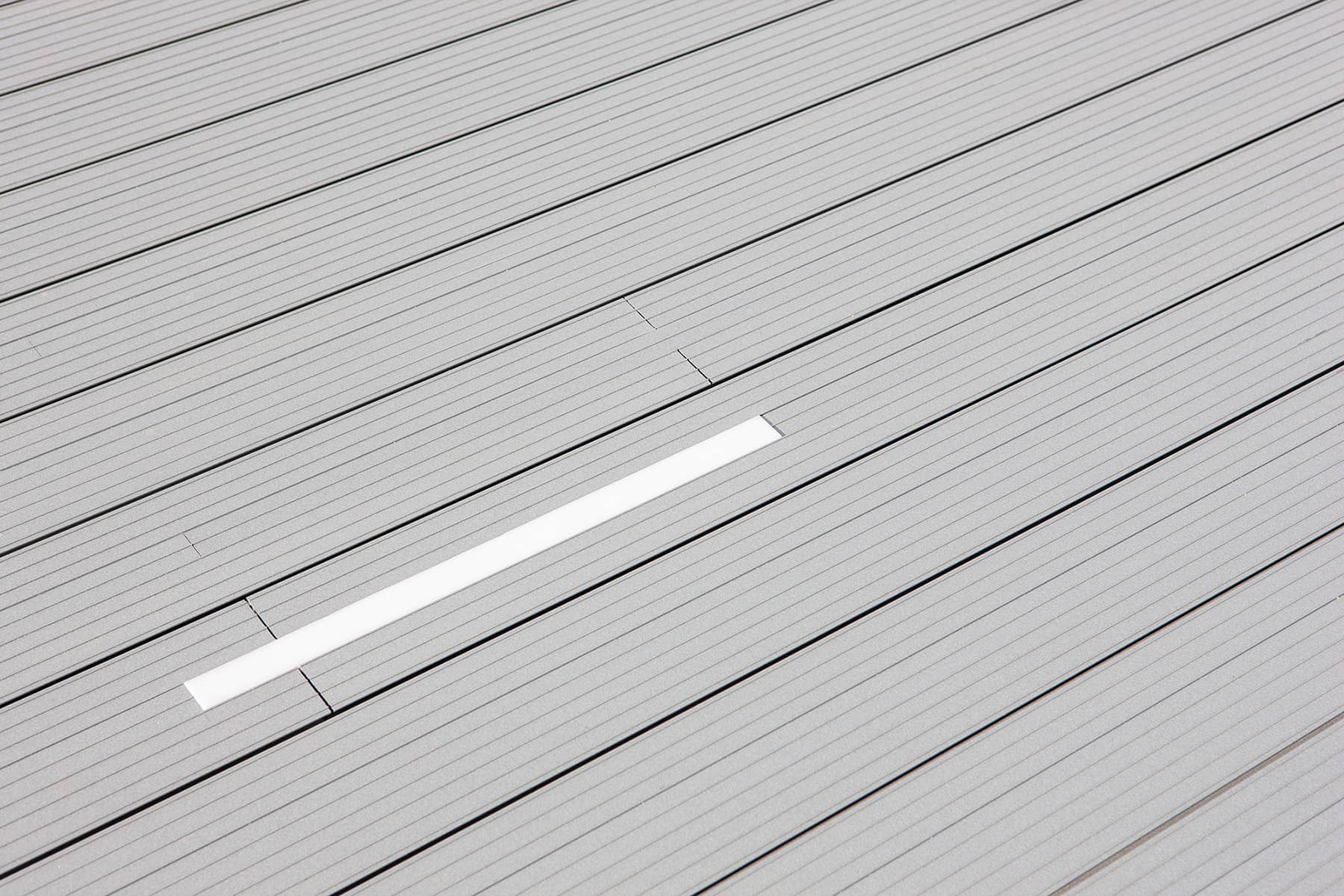

- Aluminium Decking: Lightweight, durable, and compliant with UK fire regulations, aluminium decking is a low-maintenance alternative to timber or composite materials. Delivered as pre-cut, precision-engineered panels, it is quick to install and eliminates the need for wet trades like concrete pouring or tiling.

- Integrated Drainage Systems: Modular drainage systems are built into the balcony solution, simplifying water management and reducing the need for separate installations. This ensures compliance with regulations while speeding up installation.

- Cladding and Balustrades: Pre-engineered cladding and balustrades are designed for rapid installation without compromising on safety or design. They offer a sleek, modern aesthetic while meeting stringent fire safety standards, making them ideal for residential and commercial projects.

- Fencing: Modular fencing systems are delivered as ready-to-assemble units, providing a robust, low-maintenance option that complements the overall balcony solution.

By using a single supplier for all balcony elements, developers and contractors can ensure consistency, minimise coordination issues, and significantly reduce the risk of delays.

UK Manufacturing: Reliability in Uncertain Times

One of the standout advantages of working with AliDeck is that all modular systems are manufactured in the UK. This brings several benefits to developers and contractors:

- Reliable Supply Chains: In an era where global supply chains are frequently disrupted by shipping delays and material shortages, UK manufacturing ensures a consistent and reliable supply. Components can be delivered on time, reducing the risk of delays caused by incomplete shipments or long lead times.

- High Quality: UK manufacturing allows for tighter quality control, ensuring that every component meets the highest standards of precision and durability. This reduces the likelihood of on-site errors or defects, further saving time.

- Sustainability: Local manufacturing reduces the carbon footprint associated with long-distance transportation and supports the UK’s goals for greener, more sustainable construction practices.

By sourcing products from a UK-based manufacturer, contractors and developers can build greater confidence into their project schedules, knowing that delays caused by international logistics are minimised.

Tackling Labour and Supply Chain Challenges

Labour shortages continue to affect the construction industry, making it difficult to find skilled tradespeople to complete complex, labour-intensive tasks. Modular systems help mitigate this issue by significantly reducing the amount of on-site labour required.

Similarly, the ongoing unpredictability of supply chains makes modular systems even more valuable. Since these systems are manufactured locally and delivered as complete kits, developers can avoid the risk of delays caused by multiple deliveries. This allows for better project planning and keeps construction timelines on track.

The Future of Construction: Modular Solutions

By working with a UK manufacturer like AliDeck, developers and contractors can further ensure consistent quality and timely deliveries.

In a competitive and ever-changing construction landscape, modular systems are the key to staying ahead. By embracing these innovative, time-saving solutions, you can ensure your projects are completed efficiently, sustainably, and to the highest standards—every time.

Contact us at 01622 534050 or email info@alideck.co.uk to get more information today.