AliDeck Aluminium Decking Interlocking Board

The AliDeck Interlocking Balcony Decking Board is our original non-combustible aluminium balcony decking product, offering a seamless deck surface with no gaps between the boards. It has all the same product features as our other boards, including quick installation times, a fully aluminium construction, fire resistance and our 30-year warranty, but needs to be installed with a fall (recommended 1:80) for drainage.

These aluminium metal decking boards are treated with a special powder-coating process which colours the boards in a choice of our full range of AliDeck colours. This finish along with the aluminium construction gives the boards fire ratings of A2-s1, d0 and A2fl-s1 which means they are non-combustible and provide no contribution to fire.

| Rating | Combustibility |

|---|---|

| A1 | Non-combustible/No contribution to fire |

| A2 | Non-combustible/No contribution to fire |

| B | Very limited contribution to fire |

| C | Limited contribution to fire |

| D | Acceptable contribution to fire |

| E | Acceptable contribution to fire |

| F | No performance requirements |

| Rating | Smoke Emission |

|---|---|

| S1 | Smoke emission absent or weak |

| S2 | Smoke emission of average intensity |

| S3 | Smoke emission of high intensity |

| Rating | Flaming Droplets |

| D0 | No dripping |

| D1 | Slow dripping |

| D2 | High dripping |

Fire Resistant Aluminium Metal Decking for Balconies, Terraces and Walkways

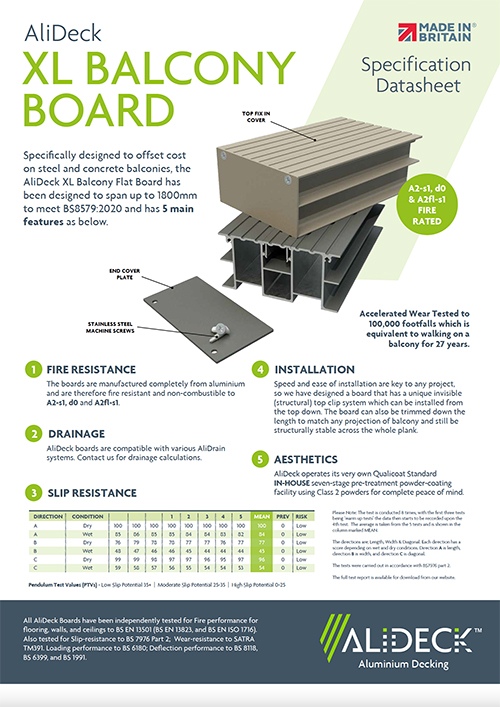

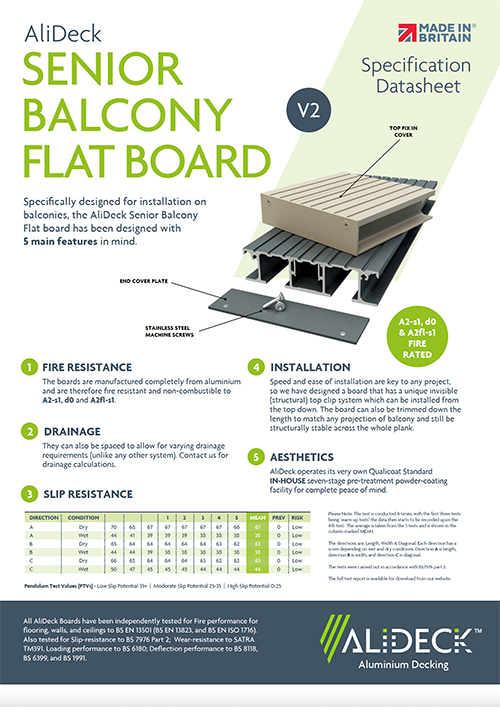

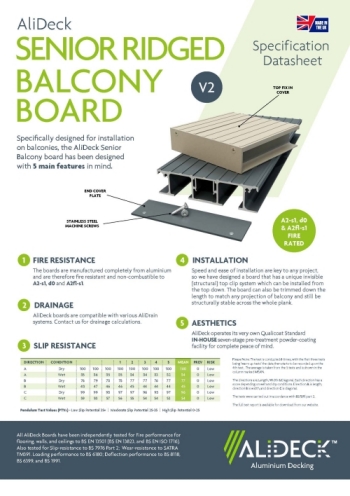

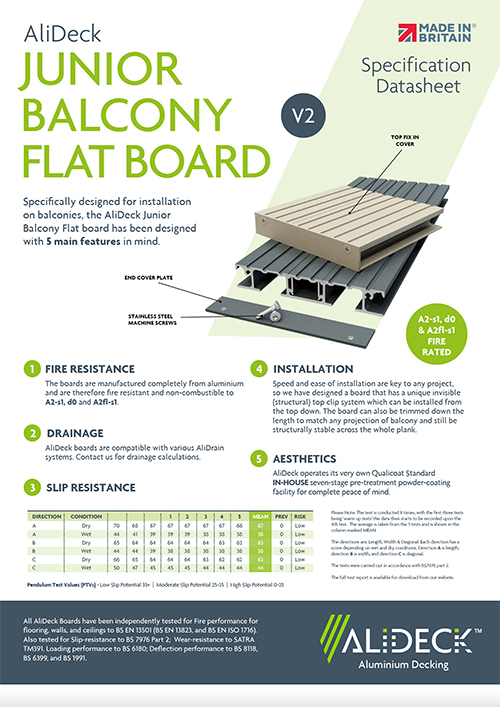

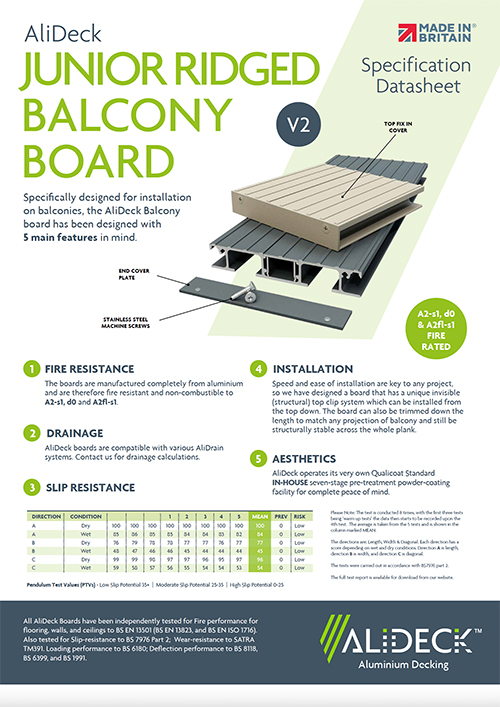

Installation

Speed and ease of installation are key to any project, so we have designed a board that is easy to work with and quick to fix to structures. The board can also be trimmed down the length to match any projection of balcony and still be structurally stable across the whole plank. The boards can be cut to size along both the length and width.

The AliDeck Aluminium decking boards are 50% quicker to install compared to other decking systems on the market. These boards are fixed from the top down so requires no fancy, fiddly fixings. It can also span 1200mm between joists on a 4kN loading.

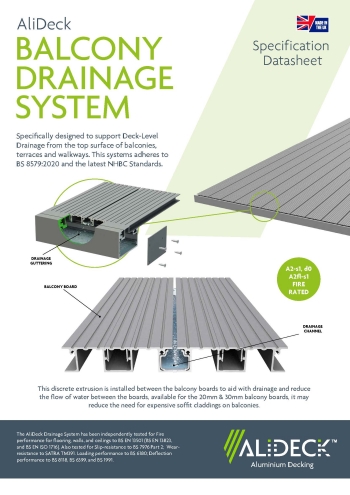

Drainage

The boards must be installed with a fall (recommended 1:80) for drainage.

Aesthetics

Aesthetics are key to a great finish; our boards are designed to look like decking but not to feel like aluminium.

Colour Options

The decking boards are available in the full AliDeck range of Qualicoat powder-coat colours.

Systemisation

All AliDeck aluminium decking boards are fully compatible with all AliDeck Joists.

Construction

The boards are constructed completely from 100% aluminium (6063 T6 grade), up to 30% of which has been recycled to make these boards eco-friendly and much better for the environment.

Maintenance

Due to the fact that AliDeck is aluminium and finished using the 5 stage Qualicoat system, little or no maintenance is required. General grime can be removed simply with a damp, lint free cloth or mop with warm soapy water.

Protective Finish

The planks are coloured using the Qualicoat powder coating finish. Qualicoat is a quality label organisation committed to maintaining and promoting the quality of coating on aluminium and its alloys for architectural applications.

Warranty

The decking is supplied with a 30 year warranty against splitting, cracking, warping, splintering, rotting, twisting and material or manufacturing defects. It has a minimum 60 year life expectancy.

AliDeck Aluminium Decking Installation Videos

AliDeck provides comprehensive performance data and test results on their website, detailing the superior performance of their products in various thermal conditions.

By aiding in the reduction of cooling costs through their thermal properties, AliDeck’s aluminium solutions are a strategic choice for enhancing the energy efficiency of buildings.

How does AliDeck’s product performance align with fire safety standards in high-temperature regions?

AliDeck’s non-combustible aluminium decking is aligned with stringent fire safety standards, offering a reliable solution for regions that experience high temperatures.

AliDeck’s inclusion of reflective RAL coloured finishes in their range is an innovation aimed at reducing heat absorption and ensuring the decking remains cool.

Evidence of AliDeck’s decking efficiency is provided by heat tests available on their website, demonstrating their decking’s ability to stay cooler under direct sunlight.

AliDeck prioritises thermal comfort in their design process, using reflective colours and coatings, and optimising airflow and shading to maintain cooler temperatures.

AliDeck utilises design strategies that include shading and heat dissipation to combat varying temperatures, enhancing the thermal performance and comfort provided by their products.

AliDeck endorses aluminium as an excellent material for balconies, terraces, walkways, and even outdoor staircases, thanks to its quick adaptation to temperature shifts, ensuring safety and comfort.

AliDeck’s aluminium drainage systems on balconies perform reliably in the heat, maintaining their function without the risk of warping or brittleness.

Aluminium, especially the T6 6063 Grade used in AliDeck products, excels at managing and dissipating heat. The thermal expansion of our products is minimal, ensuring consistent performance across all conditions. For specific tolerances, please see our Installation Guides.

AliDeck’s aluminium solutions are tailored for areas with high foot traffic, offering fast cooling and low-maintenance features that ensure consistent safety and comfort.

AliDeck leverages the rapid heat dissipation and reflective properties of aluminium to ensure that surfaces such as balconies and decking remain relatively cool.

AliDeck promotes the non-combustible nature of their aluminium products, highlighting the material’s incapacity to ignite or emit harmful fumes, which provides an added layer of safety in multi-storey buildings.

The powder coating on AliDeck’s decking acts as a barrier that minimises direct contact with the hot external environment. Although it does not completely stop heat absorption, it significantly mitigates the increase in surface temperature, making it more comfortable in sunlit areas.

While aluminium’s inherent thermal conductivity means it can warm up in the sun, AliDeck’s powder-coated finish serves as an insulator. This coating reduces direct heat absorption, thus moderating the surface temperature and enhancing user comfort.

AliDeck’s aluminium solutions are noted for their ability to maintain a stable temperature, cooling more swiftly than alternatives such as wood or composite materials.

AliDeck recognises that aluminium can absorb heat; however, due to its efficient thermal conductivity, the decking is quick to cool, often remaining at a comfortable temperature for use.

- AliDeck offer a 30 year product warranty and a 60 year life expectancy.

Our lead times are usually around 3 weeks, but these can vary. Please contact our operations team if you have any queries.

Of course, aluminium is not only corrosion resistant but our board designs and powder-coating finish provide excellent slip resistance. For exact testing figures, please see the Lite Board product page.

You can, we list many of our products on NBS Source to support project specifications for architects and specifiers.

Yes, all of our aluminium products are 100% recyclable and made from 67% recycled materials.

We are open Monday – Friday between 8am and 5pm with our dedicated team of technical experts on hand to provide any support you may require.

Samples are available for request through our website, or you can contact our sales team to arrange standard or bespoke samples to suit your project requirements.

Lead times are usually no longer than 2 weeks for bespoke orders, if you require your sample sooner, please let us know so we can try and arrange something for you. Samples can be supplied in mill finish or our Qualicoat equivalent powder-coating finish

Please contact our sales team for a free quote on your upcoming projects.

Please note: the more information you can provide, including drawings, will support or team of technical support experts to provide you with the most accurate and cost-effective pricing.

Minimum order restrictions may apply.

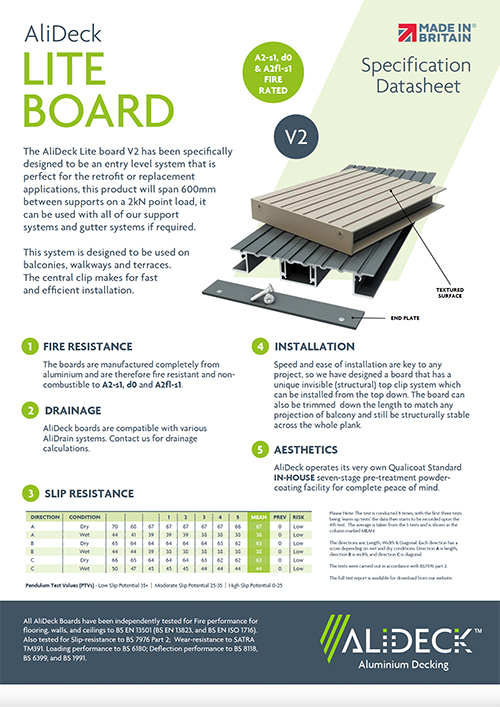

The weight of the Lite board V2 including the central clip is 1.295kg per linear metre.

More information can be found on the Lite Board product page.

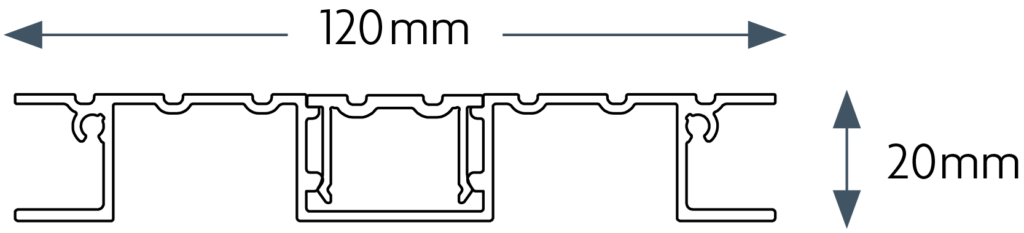

Individual board dimensions are as follows:

- Length: 4 & 6 metres

- Width: 120mm

- Depth: 20mm

More information can be found via the Lite Board product page.

You can download our free in-depth maintenance schedule on our downloads page, along with plenty of other supporting material you may require.

Residential buildings are currently designed to have a minimum expected lifespan of 60 years, our aluminium decking boards and balcony components align with this requirement.

Like with all of our products, we offer a 30 year manufacturer warranty providing you and your customers with full peace of mind.

It’s the perfect cost-effective solution for retrofit and new-build applications, if the span requirements fall within the 600mm range, and can be used with all of our support systems and gutter systems if required.

Lite board V2 has been specifically designed to innovate our entry-level system and provide a hassle-free installation. The new fixing channel design allows for ease of installation without the need for any unnecessary drilling, while the board clip provides a seamless finish.

The Lite board uses less aluminium than our Junior and Senior decking boards, making it an ideal solution for value-engineering projects. It offers a 600mm between supports on a 2kN point load.

You can find more information about the Lite Board V2 on our website. You can also contact our sales team for more information.

We always recommend our installation training; it allows us to best support your team as we seek project success together. However, if you are experienced with installing AliDeck’s Junior or Senior Decking Boards, install training is not essential.

The Lite Board V2 is ideal for a variety of projects, including:

• Remediation projects

• Refurbishment projects

• Value-engineering projects

• New build projects where steel centres are around the 600mm mark

The Lite Board V2 also has the following benefits:

• Fire rated to A2-s1,d0 & A2fl-s1

• Slip-resistant and wear-resistant

• Lightweight

• 30-year manufacturer product warranty

• Made from aluminium 6063 T6 grade

The top-fix channel system has many benefits, these include;

• Ease of installation than the previous bottom clip fixing system

• It is more secure, as the boards are fixed directly to the joists

• The new design falls in line with our other aluminium decking boards

We take product innovation very seriously at AliDeck, updating our existing products frequently. Following feedback from our customers, we felt this was a huge step in supporting their needs for hassle-free installation on future projects, at no extra cost!

The main difference between the Lite Board V1 and V2 is the fixing system. The V1 board used a bottom clip fixing system, while the V2 board uses a top-fix channel system. This makes the V2 board easier to install and in line with our other aluminium decking boards.

The AliDeck Lite Board is our entry level aluminium decking board, designed to support value-engineering and remediation projects for all of our customers and Approved Installers.

No. If you wish to close the board ends you will need to purchase AliDeck End Plates when you place your order.

We strongly recommend that fixings are stainless steel grade A2 or A4. Fixings made from other materials such as nickel-plated brass or zinc are not advised.

We strongly recommend that clearance holes are pre-drilled in the decking board. This will help to ensure that the fixing will have minimal interaction with the aluminium and minimise the risk of galvanic corrosion.

We strongly recommend that impact drivers are not used to tighten fixings when installing our products. The use of impact drivers can over-drive the fixing and cause damage to the head, weakening or potentially breaking the fixing altogether.

If we are able to use self-drilling screws on our project to fix to steelwork, what kind can we use?

When you are sure that stainless steel self-drilling screws are suitable for your application, we recommend the following;

- For steelwork less than 3mm thick, coarse-thread self-drilling screws should be used

- For steelwork greater in thickness than 3mm, fine-thread self-drilling screws should be used

It is essential that self-drilling screws with thermal washers are used. The rubber washer provides a thermal break between the screw and the decking board and reduces the risk of cross-contamination between steel and aluminium. Self-drilling screws with washers of the correct size to comfortably fit within the central fixing area of our decking boards are readily available.

Stainless steel self-drilling screws are able to be used to fix AliDeck products to steel framework. However, we strongly recommend that you understand precisely the specification and construction of the steel you are looking to fix AliDeck products to and choose the appropriate fixing to suit your specific situation.

We supply M8 bolts, nuts, and washers to fix our aluminium decking boards to our joists, but only when our boards and joists are purchased together as a decking system. We do not supply fixings when only our boards are purchased.

All AliDeck decking boards are available in stock lengths of 4m or 6m. We are also able to cut to length for a labour charge.

The depth of the AliDeck Lite Decking Board is 20mm.

The depth of the AliDeck Junior Flat Decking Board is 20mm.

The depth of the AliDeck Junior Decking Board is 20mm.

The depth of the AliDeck Senior Flat Decking Board is 30mm.

The depth of the AliDeck Senior Decking Board is 30mm.

Yes. We have produced our Certifications & Test Evidence digital booklet, which provides an overview of our fire resistance, slip resistance, wear resistance and deflection resistance testing and includes key test result data and certificates. Please visit our downloads page to access it.

Yes. We recommend a 1:80 fall, which is about 0.75 degrees.

There are several ways that we can handle your order, as follows:

Custom Extrusion

For large orders (minimum of 350KG per extrusion) we are able to arrange for custom extrusion to the precise quantity required. These extrusions are then coated and shipped direct to customers.

Stock Lengths

We hold a stock of uncoated, mill-finish decking boards and clips in 4m and 6m lengths, and joists and gutters in 6m lengths. These are then powder-coated according to order and are shipped to customer directly from our coating facility.

Cut To Length

We can cut extrusions to length for our customers. We do this at our warehouse in Rochester, Kent, and deliver from there. This service is subject to a labour charge, which varies according to quantity.

Yes. We have prepared a comprehensive Installation Guide, which is available for download at our Maintenance and Installation page.

All AliDeck aluminium metal decking products can be used in retrofit and replacement projects. We have also developed the AliDeck Lite Board and Lite Joist specifically for this market as a cost-effective, quick-fit, low-profile solution for timber and composite replacement projects.

The AliDeck Senior Balcony Board is 30mm deep. The AliDeck Junior Balcony Board and the AliDeck Lite Balcony Board are 20mm deep.

AliDeck has produced in-depth technical datasheets for all of our aluminium metal decking products. Please visit our downloads page to download them.

Yes. AliDeck has developed an online CPD with our sister company, Able Canopies. The CPD covers Fire Resistance Requirements for Balconies on Residential Buildings and will help architects gain a greater understanding of fire regulations pertaining to balcony elements and the risks of using flammable materials. Please visit our Architect’s Service page to find out more.

Yes. AliDeck metal decking boards, joists and pedestals are available in NBS Spec and BIM Library. Find out more at our Architect’s Service page.

AliDeck is committed to providing a second-to-none service to architects and specifiers as they specify products for the nation’s new homes. We have developed a central location for our Architect’s Service on our website.

Yes. You can order samples of our aluminium decking products here.

Yes. We have our latest brochure available for download here.

Yes. AliDeck provide a 30-Year Manufacturer Product Warranty for all AliDeck System products. You can view our warranty on our downloads page.

No. A simple hole through a balcony board to affix a door-stop will not void your warranty.

Yes. We recommend attaching a standard door stop using a simple nut and bolt rather than a self-tapping screw, as a nut and bolt would be a more secure option.

No. Galvanic corrosion can occur when aluminium and steel are in close proximity but all AliDeck decking boards are powder-coated on all faces to ensure the aluminium is protected. As an extra precaution, we do offer a fire-retardant tape that could be used as a barrier between the decking boards and steel framework for total peace-of-mind.

Yes. AliDeck is proud to offer the AliDeck Training Academy to help installers understand how to use our products in the best and correct way. Training is carried out at our head office in Rochester, Kent. Please visit our Training Academy page to find out more.

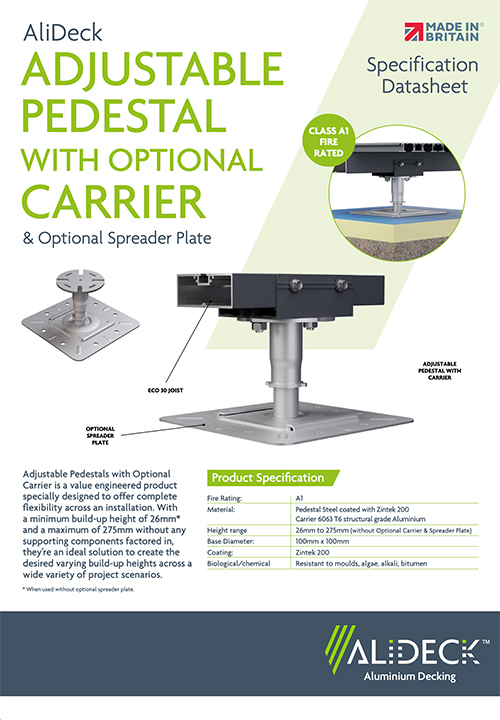

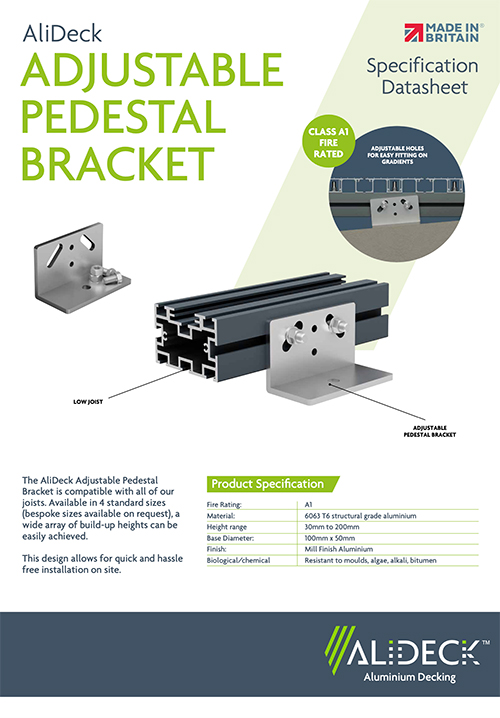

Yes. The AliDeck System has been designed as a configurable family of decking products, including boards, joists, pedestals and accessories, and all elements are inter-compatible. This allows for a wide range in flexibility as AliDeck products can be mixed-and-matched to suit your build-up height requirements.

AliDeck recommend cleaning your decking and its structure with a solution of soapy warm water and a lint-free cloth, before throughly rinsing with clean warm water. No abrasive materials should be used. Never use bleach or similar chemicals to clean AliDeck decking products. Please refer to our installation guide for more information.

AliDeck recommends that all installed elements are cleaned at regular intervals, at least twice a year, to prevent build-up of dirt and substances which may cause damage or create an increased risk of slips and trips. In coastal or industrial settings, we recommend cleaning at least every three months.

No. The AliDeck boards are powder-coated with Qualicoat, a powder-coat process for aluminium in architectural applications, which has a lifespan of 30 years and beyond.

Yes. AliDeck boards have been designed to allow pre-installation cutting, please refer to our installation guide for precise notes.

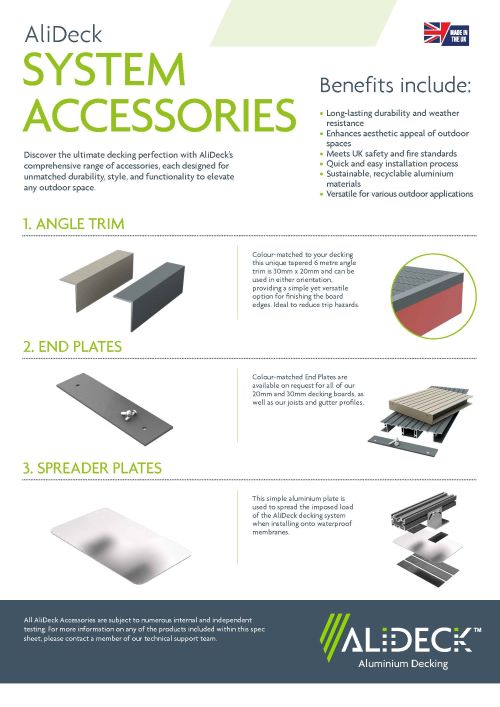

Yes. We strongly recommend that additional spreader plates or padding are used to distribute the load and prevent penetration of the waterproof membrane. AliDeck cannot be held responsible for penetration damage to existing waterproofing. If unsure of application, please contact us.

We recommend a 5mm gap is allowed between boards, but a minimum of 3mm or a maximum of 8mm is acceptable.

Yes. All AliDeck A-rated boards, joists, pedestals and accessories are fully compliant with all fire-safety legislation, meeting and exceeding all recent updates.

The Euroclass ratings have several elements which each indicate a performance rating. The first element regards combustibility and is fire rated from A to F, with A representing non combustible materials.

The second element relates to smoke emission level and is rated 1 to 3, with 1 indicating smoke emission as weak or absent.

The third element relates to the production of flaming droplets and is rated 0 to 2, with 0 indicating no droplets produced.

Finally, the inclusion of “fl” indicates that the products have been specifically tested for flooring applications.

Yes. All elements* of the AliDeck System have been fire tested for fire safety and are Euroclass A-rated, achieving A2,s1-do and A2fl-s1 certification.