AliDeck Service for Developers and Contractors on Aluminium Decking Products

With the construction industry now forced to adapt to the changes and recent updates to fire safety regulations we are all aware of the requirement to ensure that materials and practices are fully-compliant with legislation.

Moreover, the sourcing of approved products and materials availability is added to the challenge of meeting pre-determined budgets and build programmes, not to mention seemingly endless rounds of comment, review and amendment of design drawings. AliDeck can help to greatly accelerate this process by our timely intervention and preparations before final approval processing.

Based on the simple principle of ‘facilitation’, our specialist teams are available to offer the fullest assistance. Whether your need is for Balcony Decking, or Metal Deck Flooring in the broader sense, or the replacement of non-compliant Wood or Composite Decking, our innovative, proven and fully compliant solutions are now being widely adopted by your peers.

Our ‘facilitation’ approach, developed from over 20 years of working closely with Developers, Contractors, and Project Managers, is based on our full understanding of your challenges and concerns – these boil down to compliance, design viability, cost-effectiveness, material availability, performance and durability, warranty, life expectancy and ultimately, you having confidence in the choices you make. Alongside these essentials, we recognise the importance of speed and accuracy in grasping your needs, with attention to detail and enquiries serviced with swift, considered responses.

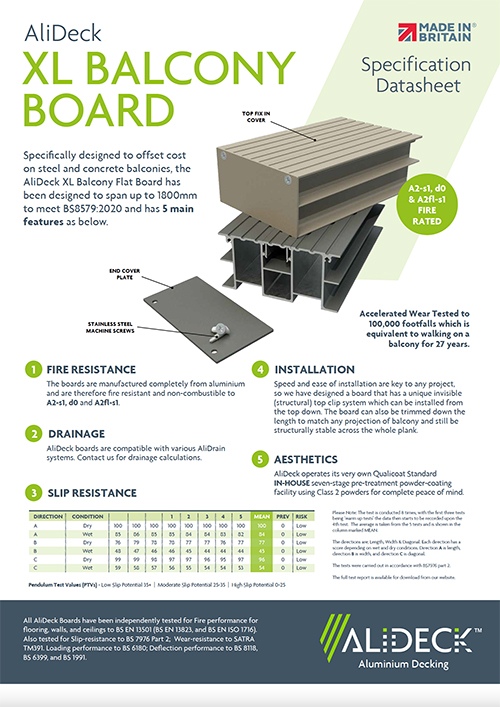

AliDeck Product Technical Data and Test Certification

AliDeck is committed to providing total peace-of-mind to contractors and developers when choosing our range of aluminium metal decking products.

Accordingly, we have developed a full suite of detailed technical datasheets to assist architects when specifying the AliDeck System. Additionally, we are delighted to publish and share the results of our extensive product testing on fire safety, slip resistance, wear resistance and our time & motion study. We are also proud to offer a 30 year manufacturer product warranty for all of our AliDeck System components.

Finally, for projects that might have unique features and specific requirements to consider when choosing the AliDeck System, we are more than happy to produce and supply additional bespoke documentation and design on request.

We recommend a 5mm gap is allowed between boards, but a minimum of 3mm or a maximum of 8mm is acceptable.

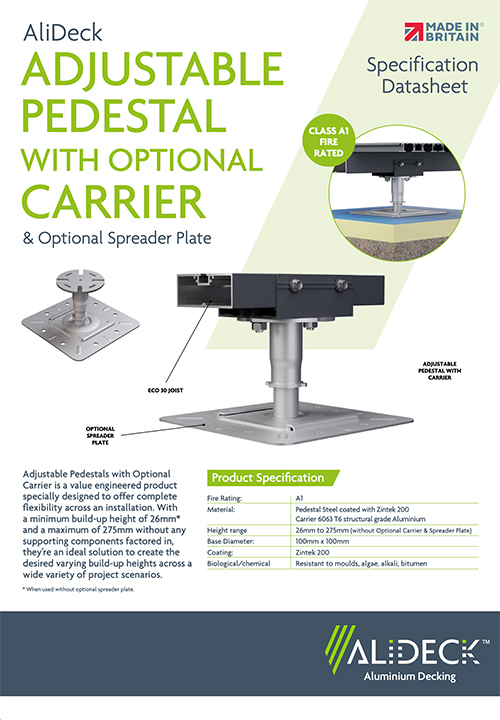

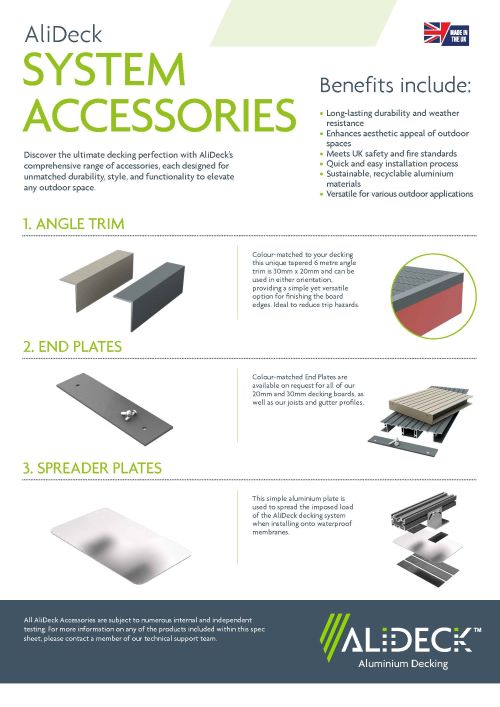

Yes. We strongly recommend that additional spreader plates or padding are used to distribute the load and prevent penetration of the waterproof membrane. AliDeck cannot be held responsible for penetration damage to existing waterproofing. If unsure of application, please contact us.

Yes. AliDeck boards have been designed to allow pre-installation cutting, please refer to our installation guide for precise notes.

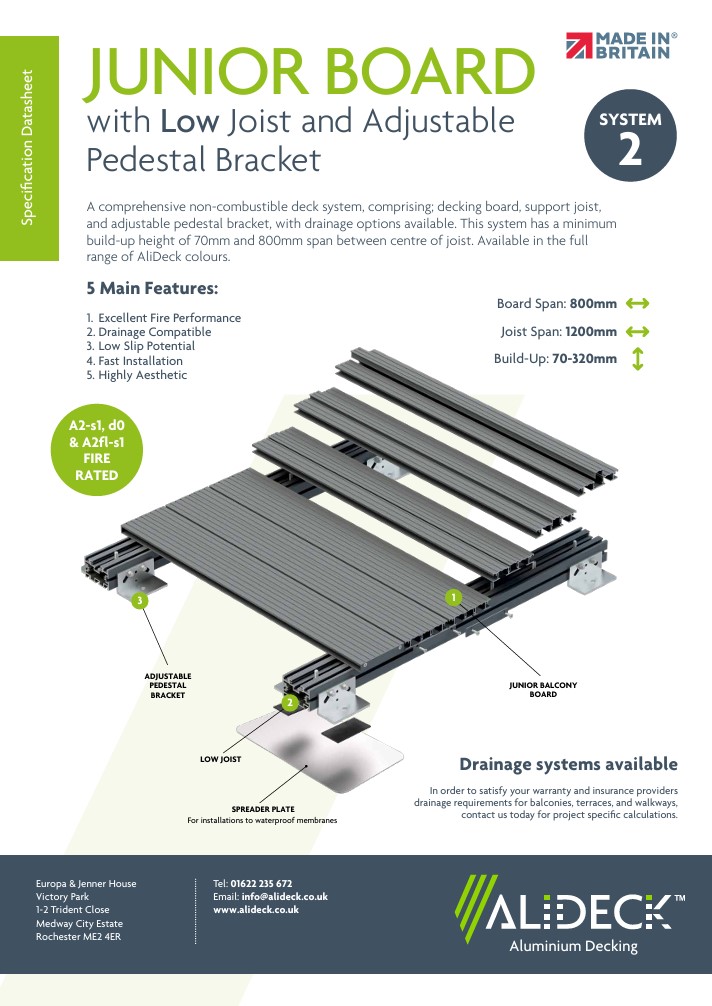

Yes. The AliDeck System has been designed as a configurable family of decking products, including boards, joists, pedestals and accessories, and all elements are inter-compatible. This allows for a wide range in flexibility as AliDeck products can be mixed-and-matched to suit your build-up height requirements.

Yes. AliDeck is proud to offer the AliDeck Training Academy to help installers understand how to use our products in the best and correct way. Training is carried out at our head office in Rochester, Kent. Please visit our Training Academy page to find out more.

No. Galvanic corrosion can occur when aluminium and steel are in close proximity but all AliDeck decking boards are powder-coated on all faces to ensure the aluminium is protected. As an extra precaution, we do offer a fire-retardant tape that could be used as a barrier between the decking boards and steel framework for total peace-of-mind.

Yes. We recommend attaching a standard door stop using a simple nut and bolt rather than a self-tapping screw, as a nut and bolt would be a more secure option.

No. A simple hole through a balcony board to affix a door-stop will not void your warranty.

Yes. We have prepared a comprehensive Installation Guide, which is available for download at our Maintenance and Installation page.

Yes. We recommend a 1:80 fall, which is about 0.75 degrees.

We supply M8 bolts, nuts, and washers to fix our aluminium decking boards to our joists, but only when our boards and joists are purchased together as a decking system. We do not supply fixings when only our boards are purchased.

Stainless steel self-drilling screws are able to be used to fix AliDeck products to steel framework. However, we strongly recommend that you understand precisely the specification and construction of the steel you are looking to fix AliDeck products to and choose the appropriate fixing to suit your specific situation.

If we are able to use self-drilling screws on our project to fix to steelwork, what kind can we use?

When you are sure that stainless steel self-drilling screws are suitable for your application, we recommend the following;

- For steelwork less than 3mm thick, coarse-thread self-drilling screws should be used

- For steelwork greater in thickness than 3mm, fine-thread self-drilling screws should be used

It is essential that self-drilling screws with thermal washers are used. The rubber washer provides a thermal break between the screw and the decking board and reduces the risk of cross-contamination between steel and aluminium. Self-drilling screws with washers of the correct size to comfortably fit within the central fixing area of our decking boards are readily available.

We strongly recommend that impact drivers are not used to tighten fixings when installing our products. The use of impact drivers can over-drive the fixing and cause damage to the head, weakening or potentially breaking the fixing altogether.

We strongly recommend that clearance holes are pre-drilled in the decking board. This will help to ensure that the fixing will have minimal interaction with the aluminium and minimise the risk of galvanic corrosion.

We strongly recommend that fixings are stainless steel grade A2 or A4. Fixings made from other materials such as nickel-plated brass or zinc are not advised.

No. If you wish to close the board ends you will need to purchase AliDeck End Plates when you place your order.

AliDeck offer a full design solution for developers and contractors to provide a truly bespoke materials provision for your projects. With our free take-off and quote service, we can help you build the perfect aluminium decking specification to ensure hand-in-glove fit to your plans and maximum cost-effectiveness.

Rigorous scrutiny by UK testing facilities has confirmed full compliance with current UK and European standards for fire safety, slip resistance performance and inarguable longevity, as evidenced by the results of accelerated wear tests. All AliDeck products are backed by our 30-year manufacturer product warranty.

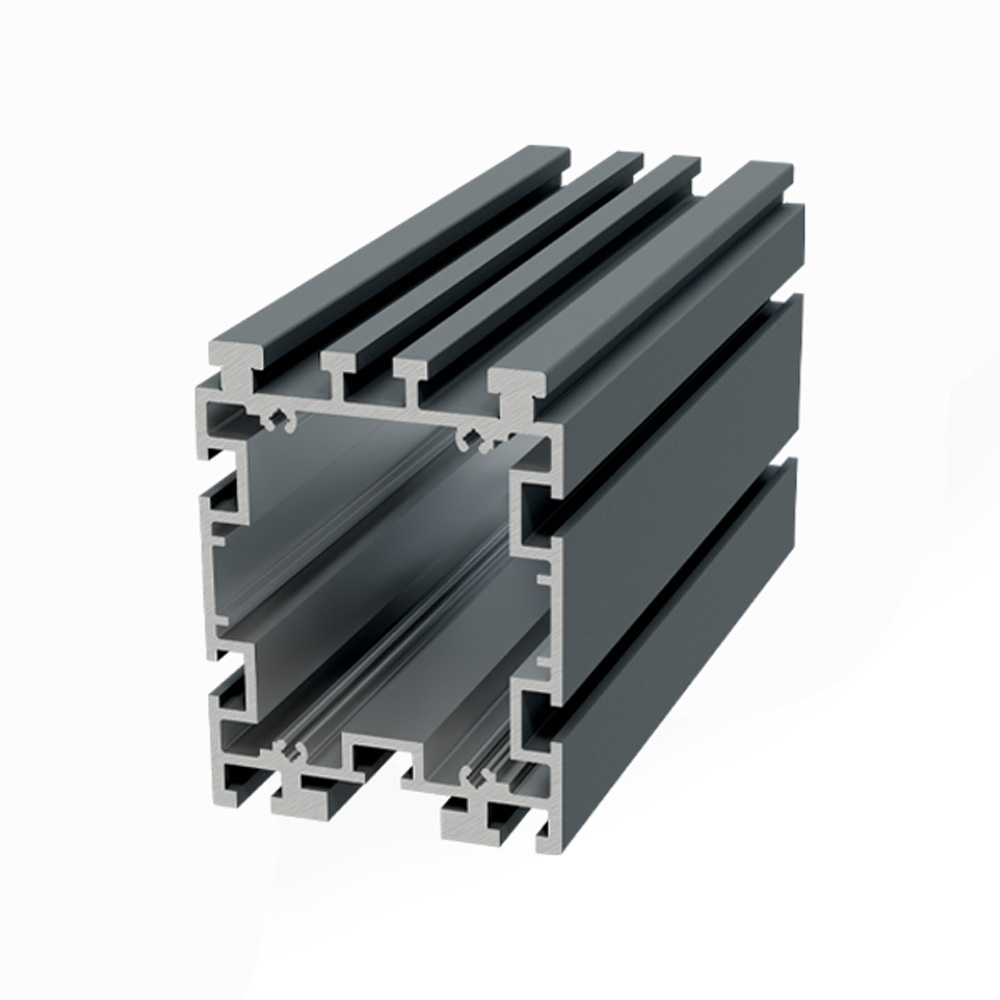

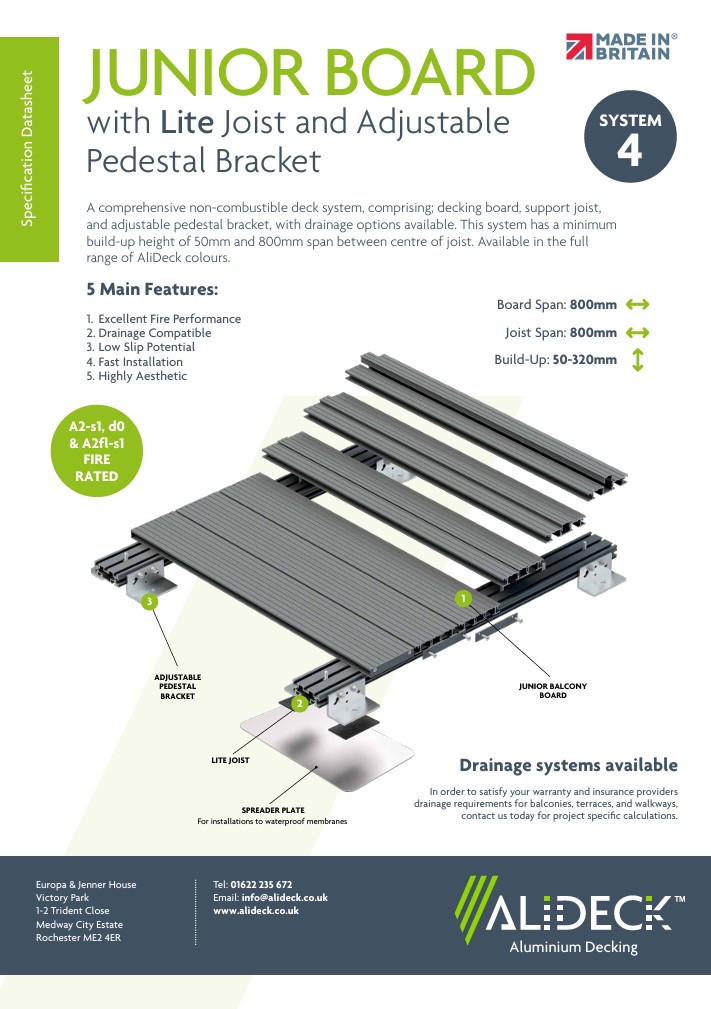

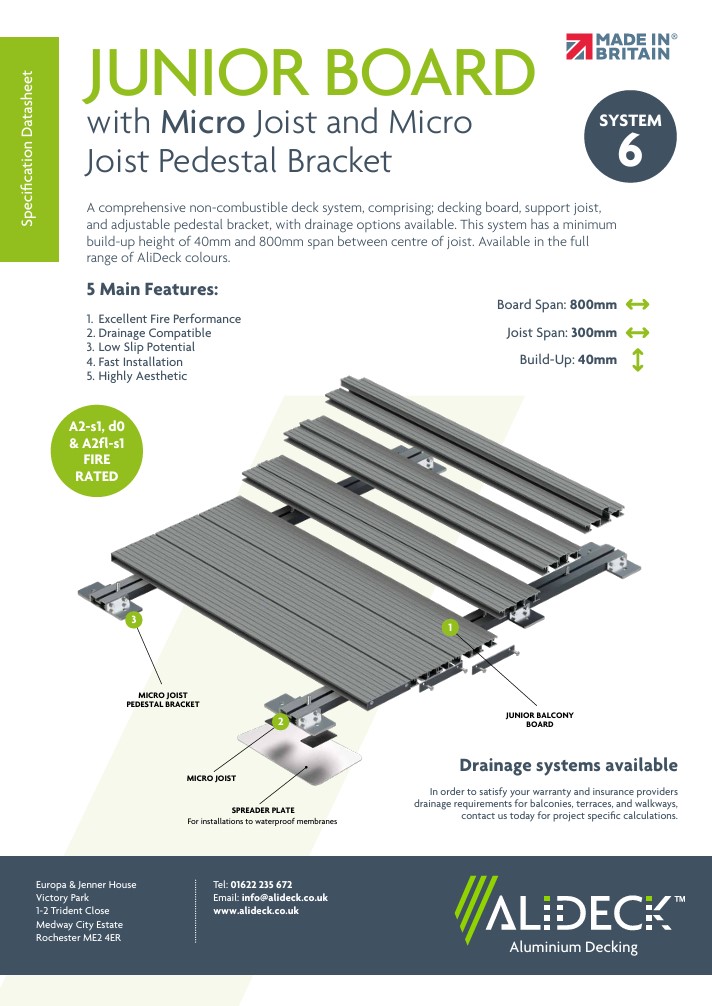

The AliDeck Aluminium Decking System is a compatible family of products designed to work seamlessly together in any configuration to solve your challenges

AliDeck have co-developed a unique family of aluminium decking products, intelligently designed to satisfy all balcony, terrace and walkway requirements, including new-build and retrofit/replacement.

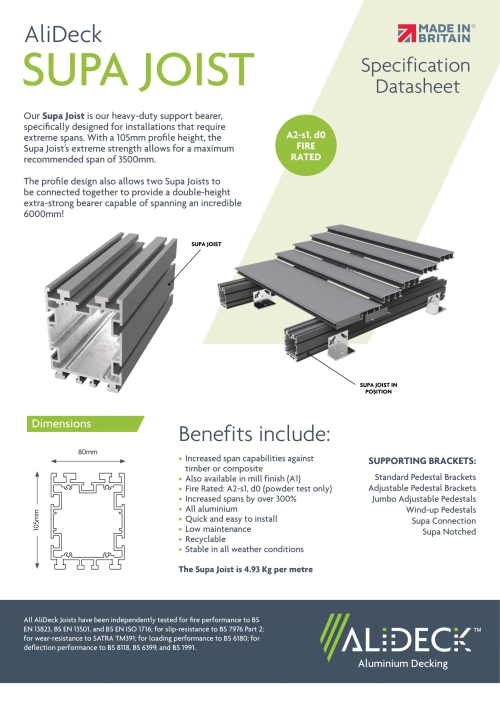

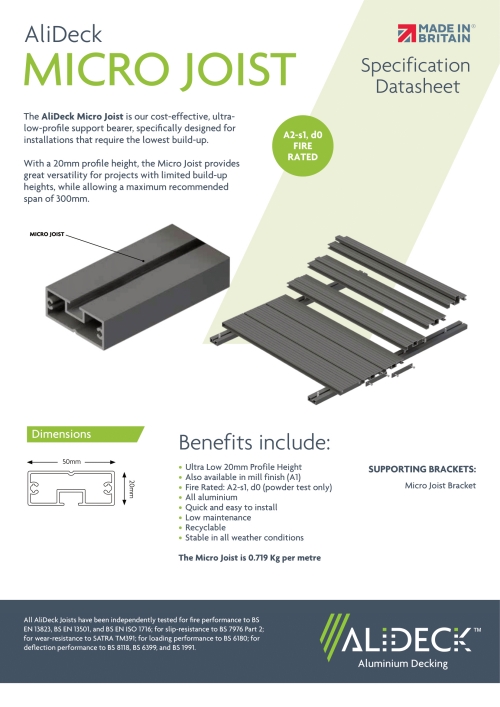

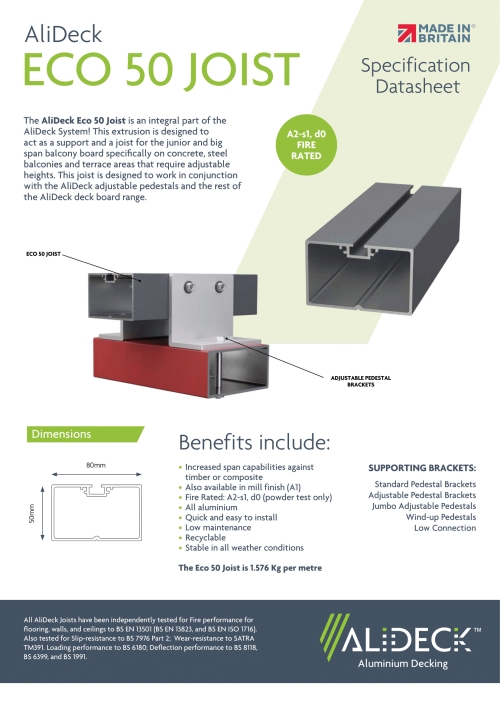

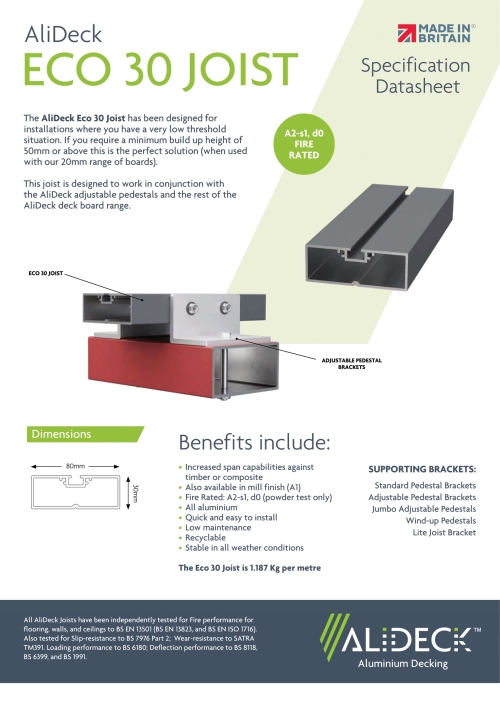

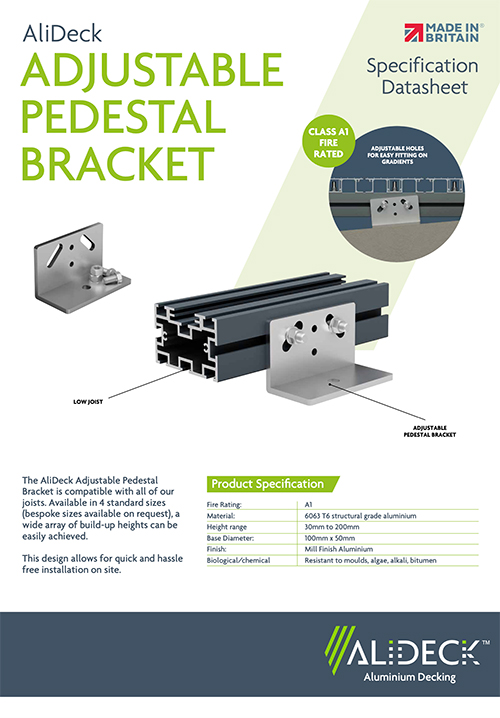

Consisting of Decking Boards, Supports Joists, Adjustable Pedestals and Decking Accessories, the AliDeck System delivers all the options that developers and contractors need when planning their projects.

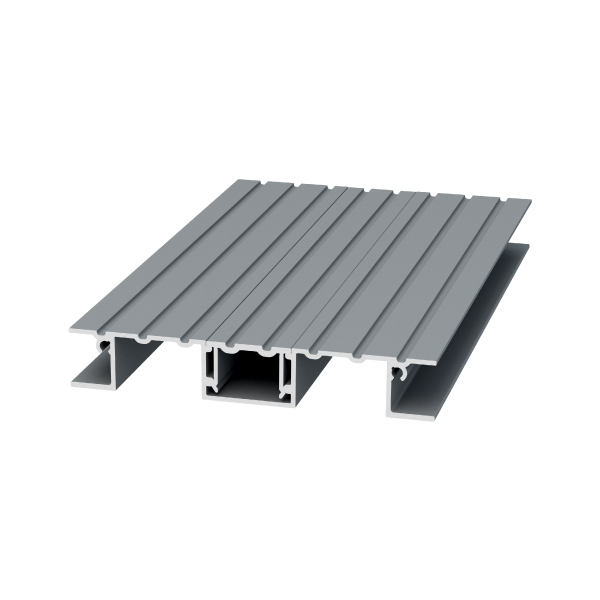

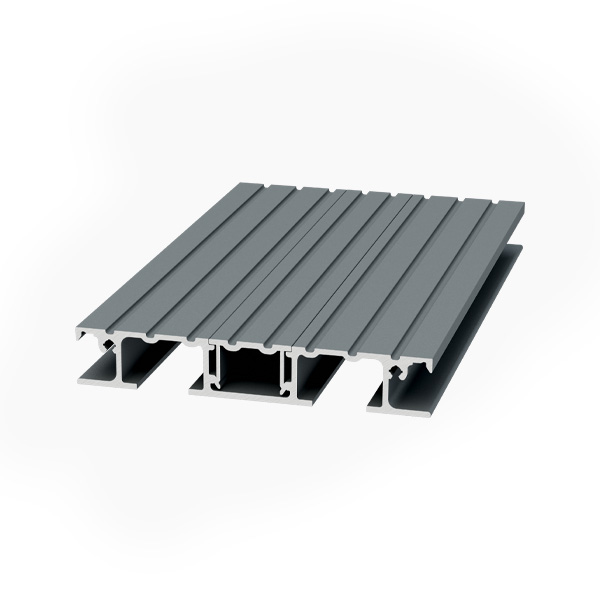

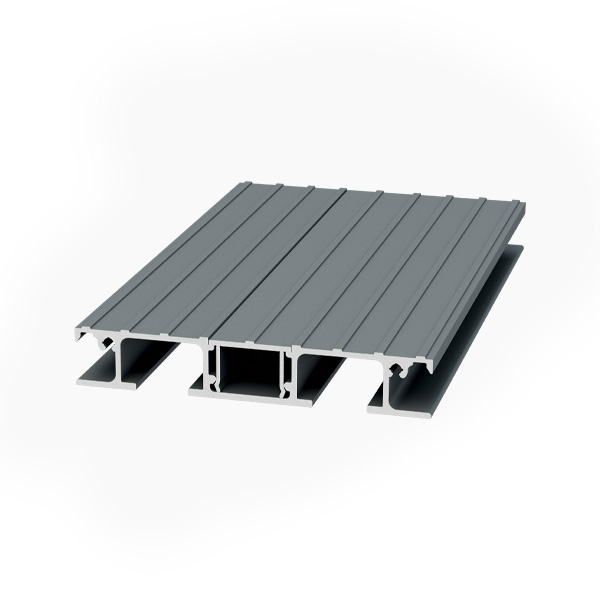

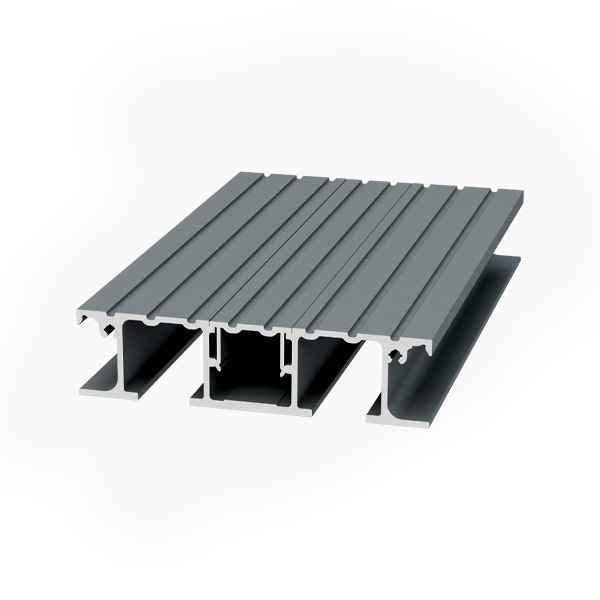

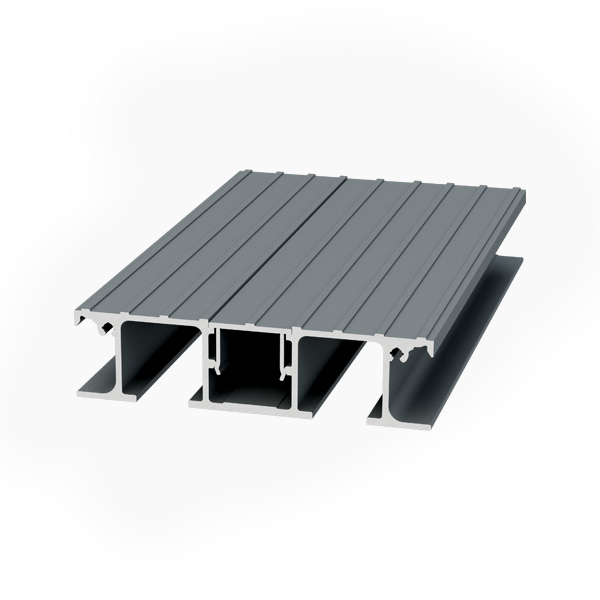

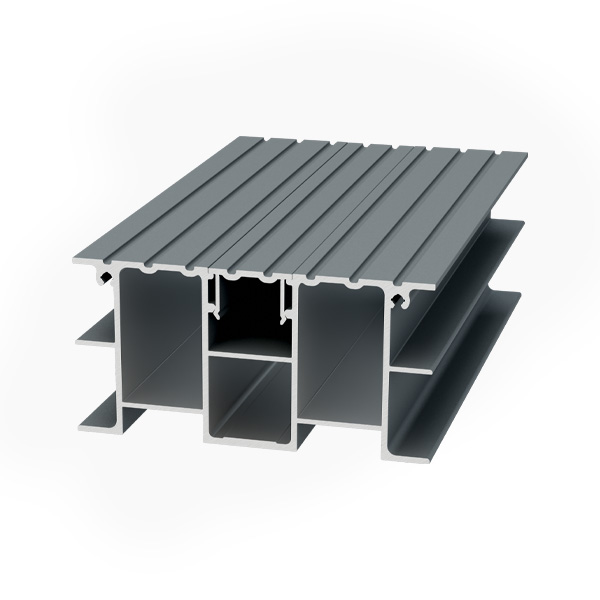

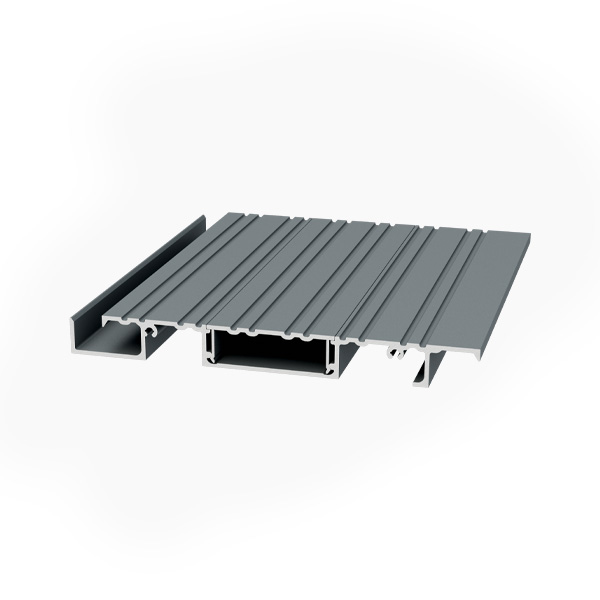

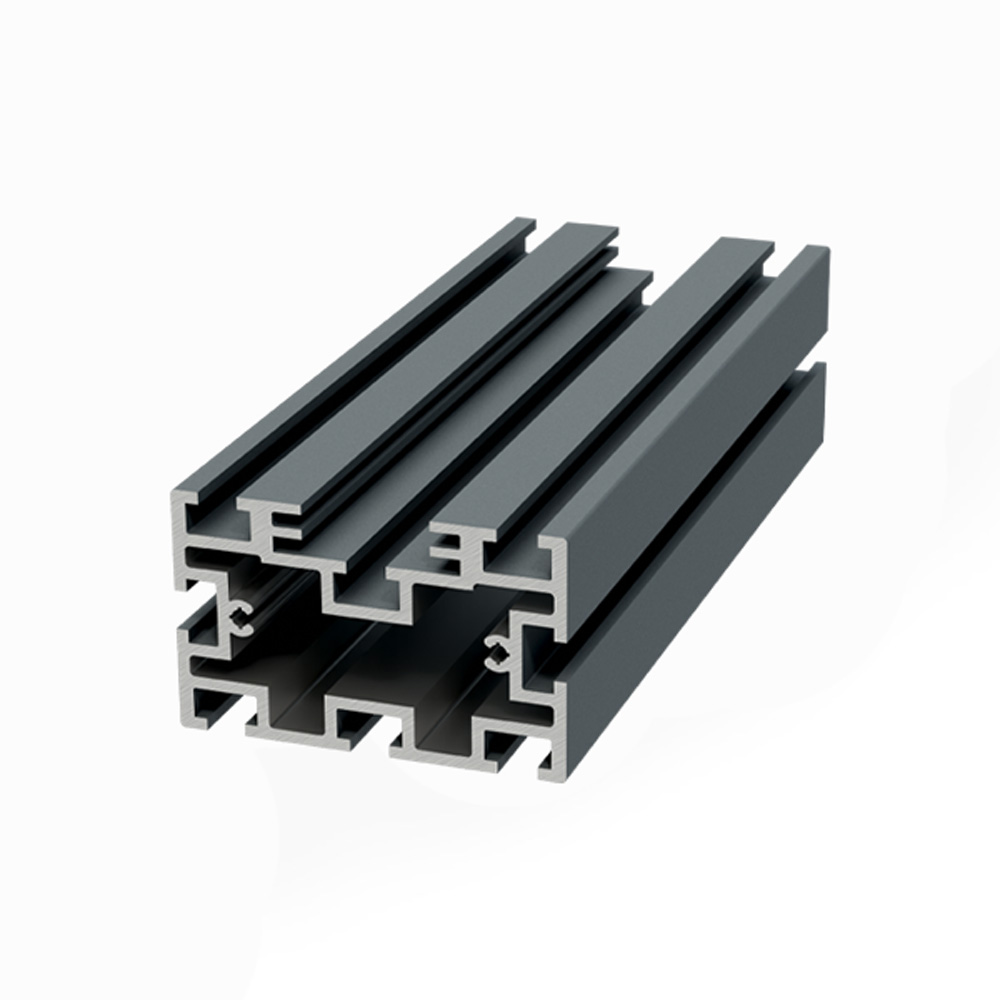

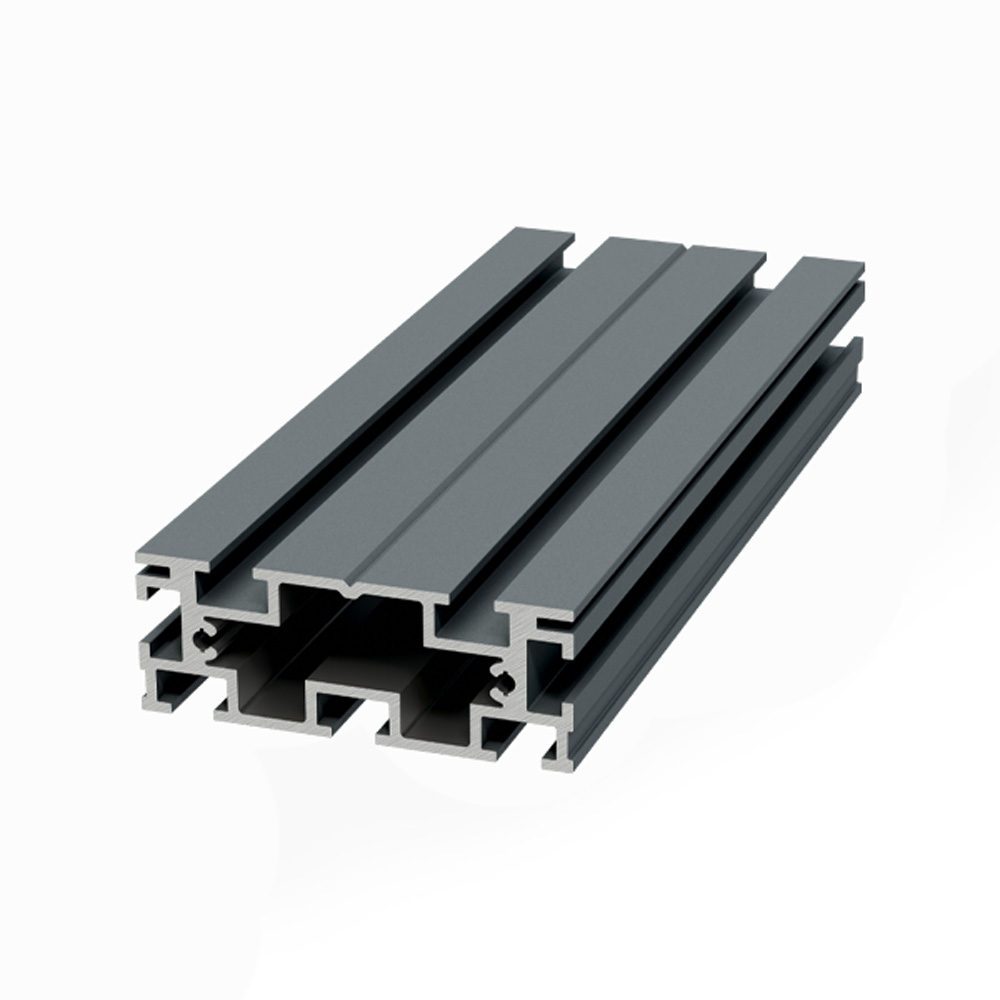

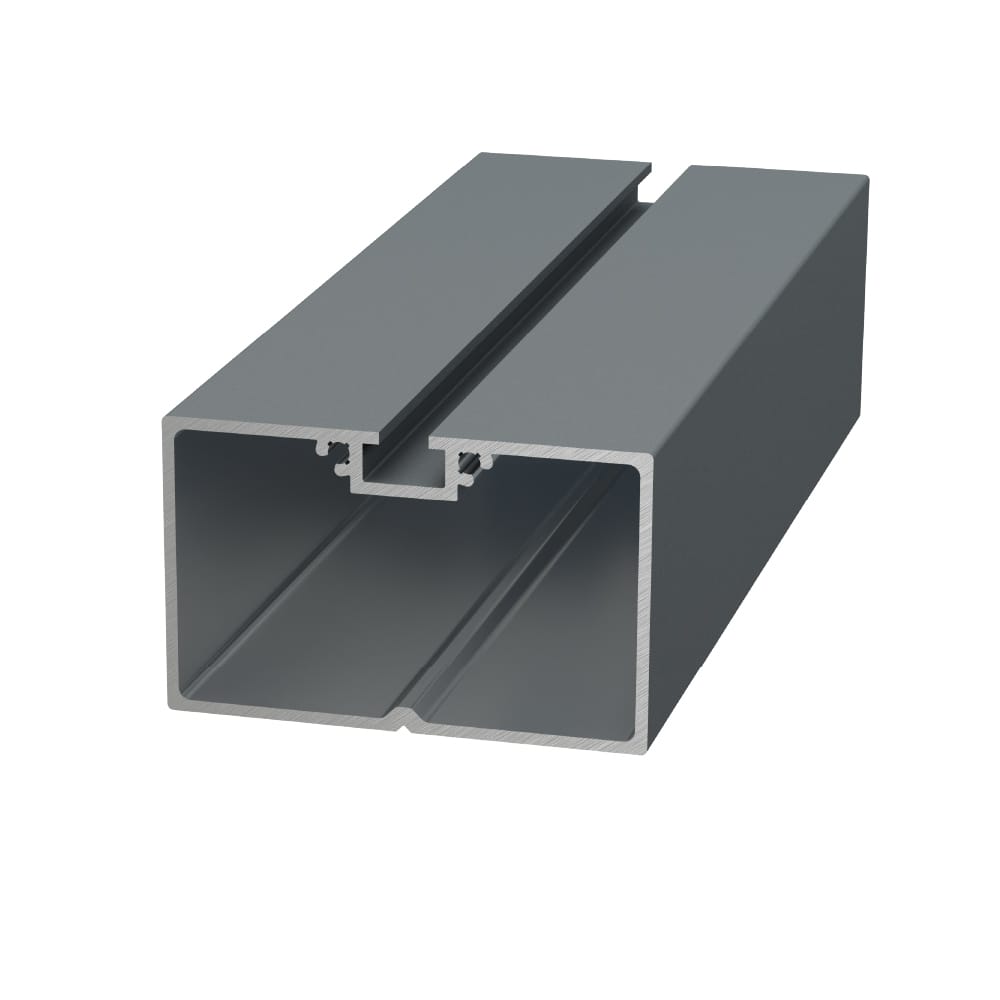

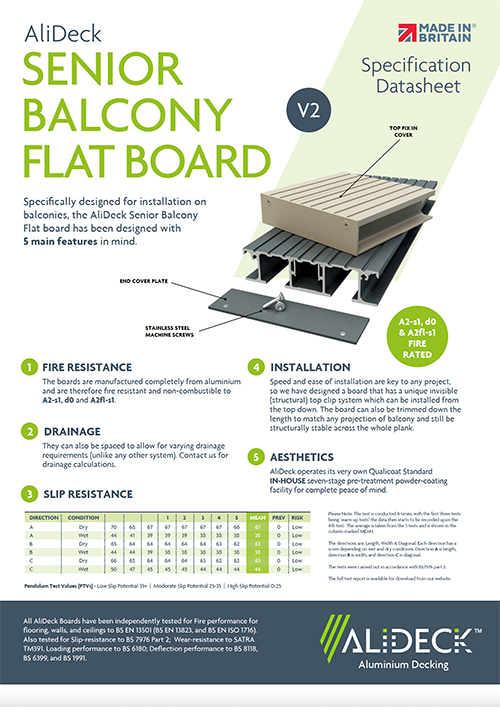

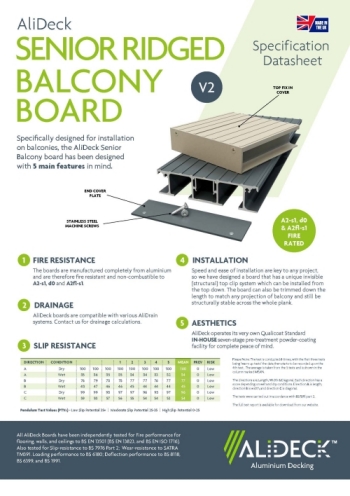

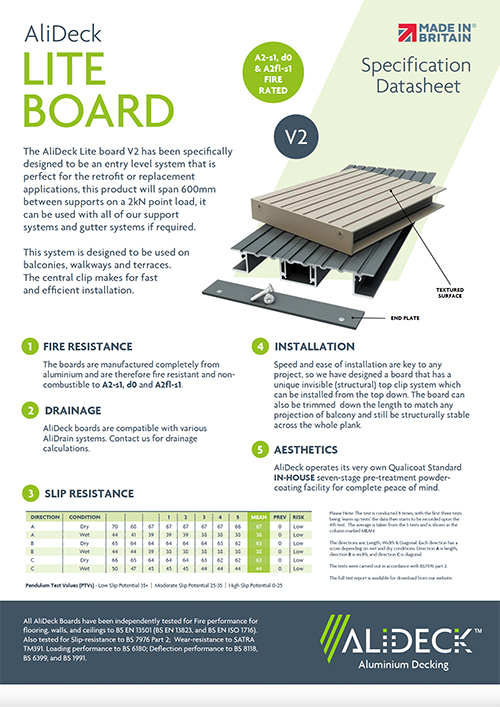

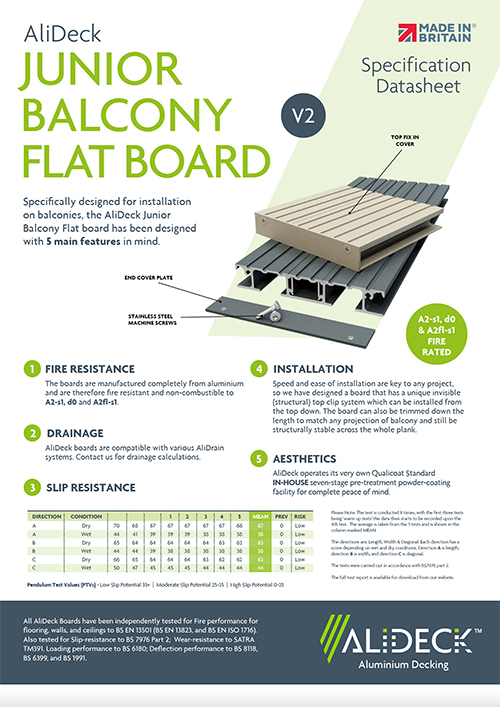

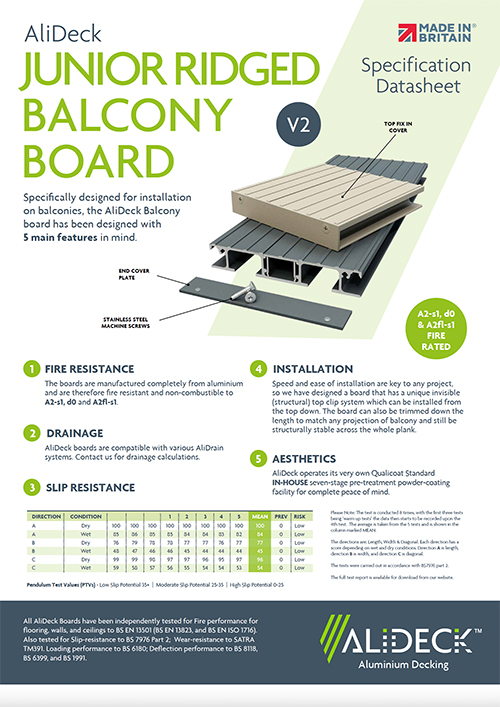

AliDeck Aluminium Decking Boards

AliDeck manufacture a range of aluminium decking boards, each tailored to specific scenarios to offer a diverse range of options to meet your project needs.