Expansion of aluminium decking due to temperature is minimal but must be considered at installation

When choosing the materials for a project, there are many boxes that must be ticked to ensure a successful outcome. Thermal expansion is one factor that impacts all materials as they react to the environment, which can vary greatly in the UK from season to season. In the balcony construction market, aluminium has proven to be an excellent thermal conductor and has delivered excellent benefits to industry on expansion.

Aluminium is rapidly becoming the de facto standard material for many aspects of construction, but particularly for balcony manufacturers. Traditionally, balcony decking would use timber or composite decking, two combustible materials with a far shorter life expectancy. AliDeck released the first aluminium decking boards in the UK in 2015 and introduced a new outlook for effective balcony and terrace flooring.

Like all materials, aluminium expands and contracts due to temperature but close examination show that the margins are in fact very little. Timber and composite decking suffer significantly more but aluminium does still react to temperature, and it should be taken into account when installing.

Certainly, when butting boards end to end, thermal expansion is a genuine concern in areas of high exposure to sunlight. This is especially of concern in areas where sunlight can be reflected and concentrated onto the decking by glass walls or large windows on a roof terrace. Temperatures can reach extremes in the height of summer as we saw in June when temperatures reached a record high of 40.3°C, as well as lows of around -10°C in winter.

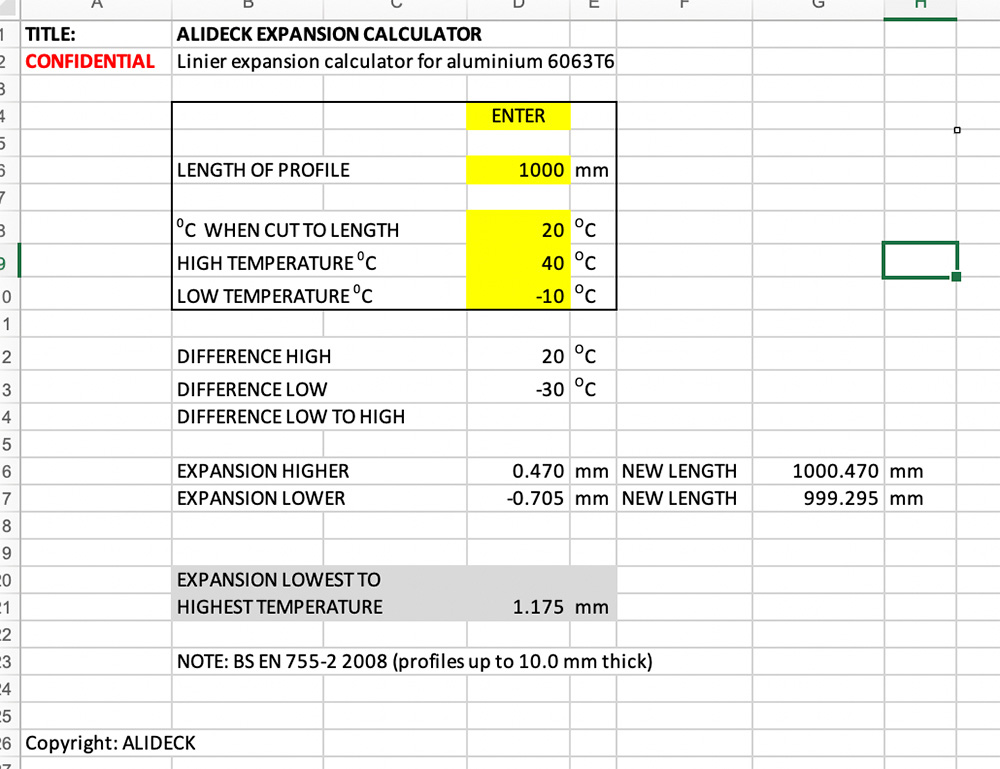

We do have an internal tool, created by our resident structural engineer and aluminium expert, that we can use to calculate linear expansion of aluminium profiles. The tool is predicated on BS EN 755-2: 2008, using the modelling values for extruded aluminium profiles of up to 10mm wall thickness.

When inputting a 1000mm board length, and assuming it was cut to length when its temperature is 20 degrees Celsius, setting the expected maximum temp of 40 degrees and expected minimum temperature of -10 degrees, the total range of expansion and contraction is only 1.175mm to the linear metre of aluminium decking board.

This excellent performance shows aluminium to be minimally reactive to expansion or contraction due to temperature. This stability of the material means that there will be significantly less environmental wear and tear over its lifespan when compared to timber or composite material.

Despite this stability, caution must still be applied at installation and a tolerance should be factored in when determining expansion gaps, particularly when boards are butting end-to-end, close to other structures, or when mitred together. For project-specific advice, you can contact the AliDeck team to discuss your precise requirements and we will be happy to help you achieve a perfect installation.

If you would like to discuss any of the content within this article in more depth, please contact us on 01622 235 672 or email us at info@alideck.co.uk.