AliDeck factory build and ship full non-combustible aluminium balcony component system sample to customer

It has been great to see the AliDeck factory team settle into their new home in our state-of-the-art 65,000 square foot headquarters in Rochester.

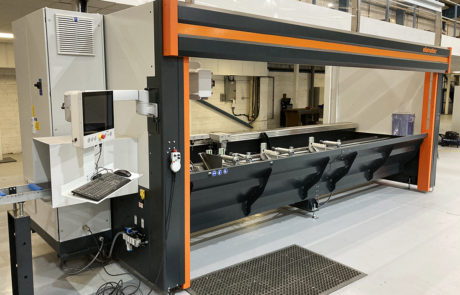

Following our recent move to our new base, we have scaled up our entire manufacturing operation to create the UK’s leading aluminium decking and balcony component manufacturing facility. Our production area is now furnished with some seriously high-end machinery to help us unlock new workflows. At the heart of it all are our new double mitre saw and CNC profile machining centre.

These high-end Elumatic machines are now enabling us to complete complex orders of our range of aluminium decking, soffit cladding, and balustrades quickly and efficiently. With tolerances below 0.01mm, this factory production process delivers the scale and repeatability our customers need.

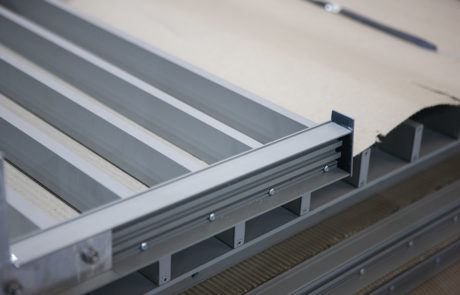

We were delighted, then, to see this machinery in action for the first time to produce sample balcony kits for our steel fabricator customer. Comprising our full suite of products, this balcony kit was designed first in SolidWorks to create the detailed CAD required to program the machinery. It was then a simple task to create the constituent parts for the decking, cladding and balustrades.

Roger, our Machine Manager, and his team then swung into action to build the AliRail Vertical Spindle Infill balustrade elevations and prepare the whole order for shipping in kit form. Once with our fabricator customer, it will be a straightforward assembly task to fit the decking, cladding and balustrades to their steel frame ready for transport to site for installation.

This is a milestone for AliDeck in our journey and a clear indication of our aspirations to become the UK’s foremost supplier of balcony component solutions to the industry.

To find out more about AliDeck’s full suite of solutions call the team on 01622 235 672 or email info@alideck.co.uk.