Information on how to install and maintain AliDeck Aluminium Metal Decking

The AliDeck System of aluminium metal decking products has been carefully designed and engineered to be a quick-fit, easy to install decking system with features tailored to efficient and successful installation. The AliDeck System has also been rigorously tested for durability and wear-resistance, achieving excellent results across the board.

All that said, however, there are some important installation and maintenance tips and best-practices to ensure satisfaction and a long and happy life for your AliDeck decking. Please closely read the information on this page and in the downloadable documents. If you have any further questions regarding installation or maintenance, the AliDeck team are here to help; call us on 01622 235 672 or email info@alideck.co.uk.

Cutting and Shaping Your Aluminium

When cutting or shaping your on-site decking you may require some in-expensive tools, we recommend the following to help you install our product safely:

Chop Saw

In order to cut the decking on site the best thing you can use would be a chop saw, the decking is really easy to cut so nothing special will be needed with regards to type. AliDeck’s CEO personally uses the following machine with an aluminium blade: DeWALT 240v Mitre Saw

Blade

The blade you will need would be the following type: Freud 216mm Blade with 30mm Bore Diameter

Circular Saw

If you would like to cut the boards down the length, then you can use an evolution circular saw with a TCT multi material blade as shown in the cutting video below. Evolution 1600w 185mm Circular Saw

Cutting Disc

We also notch the decking using a skinny (cutting) disc on a grinder, something like the following would be perfect: Norton 5” Cutting Disc

Regarding cutting to length in a factory, we would recommend the following to cut to length: Non-Ferrous Semi-Automatic Circular Saws

How to Cut the AliDeck Aluminium Decking Boards to Width

Watch the video below to find out how to cut our aluminium decking boards along the width to fit the area required.

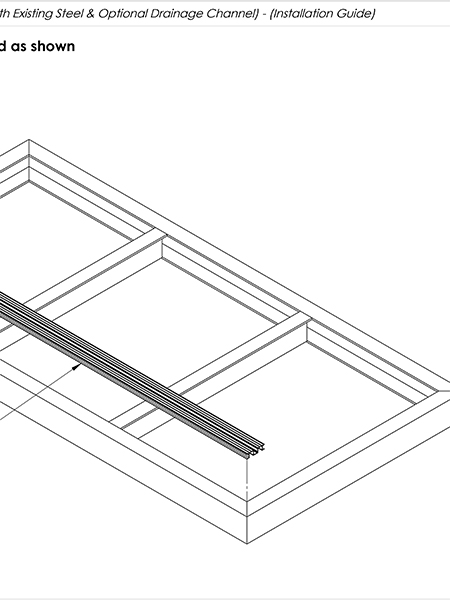

Fixing AliDeck products to steel framework

It is essential that your fixings are stainless steel grade A2 or A4. Fixings made from other materials such as nickel-plated brass or zinc are strongly not advised.

In most cases, stainless steel self-drilling screws are able to be used to fix AliDeck products to steel framework. However, we strongly recommend that you understand precisely the specification and construction of the steel you are looking to fix AliDeck products to and choose the appropriate fixing to suit your specific situation.

When you are sure that stainless steel self-drilling screws are suitable for your application, we recommend the following;

- For steelwork less than 3mm thick, coarse-thread self-drilling screws should be used

- For steelwork greater in thickness than 3mm, fine-thread self-drilling screws should be used

Self-drilling screws are available to purchase from ToolStation, but alternative vendors will also stock suitable screws.

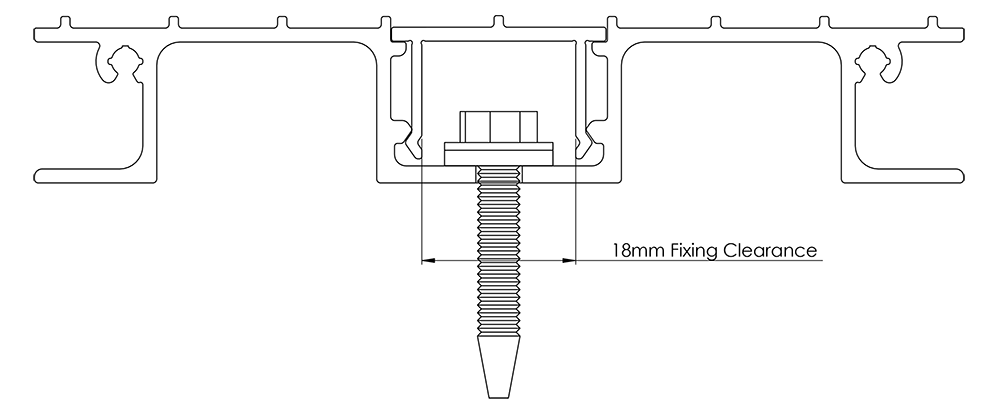

It is essential that self-drilling screws with thermal washers are used. The rubber washer provides a thermal break between the screw and the decking board and reduces the risk of cross-contamination between steel and aluminium. Self-drilling screws with washers of the correct size to comfortably fit within the central fixing area of our decking boards are readily available.

When applying these fixings, care must be taken to not over-drive the screws. We strongly recommend that impact drivers are not used as the increased torque can easily crack or even completely break the head of the screw. When the head of the screw is cracked, the natural flexing of the decking boards under use may eventually cause the weakened screw to break away completely.

It is important to pre-drill a clearance hole in the decking board before you use the self-drilling screws. This will help to ensure that the fixing will have minimal interaction with the aluminium and minimise the risk of galvanic corrosion.

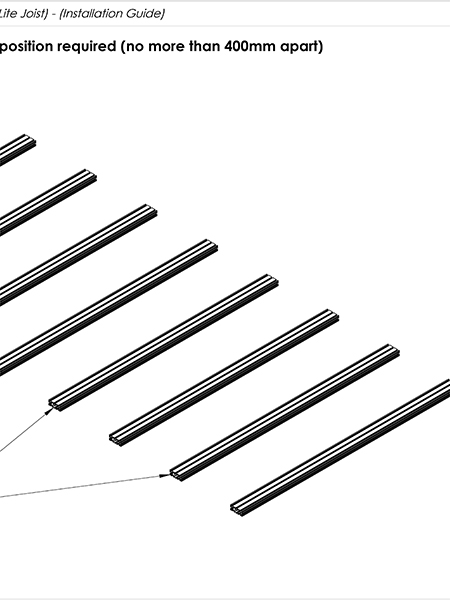

Install Method: Staggered Placement of Boards and Clips

An excellent method of installation of AliDeck decking boards is to stagger the placement of boards and clips. This adds strength to the deck surface by knitting the boards together better and also breaks up the visual impact of board and clip joins. Please watch the following explainer video to understand more.

When manufacturing an order, we coat the boards and clips at the same time. It is important to not mix up boards and clips from different production batches as there may be minor differences in coating finish between batches.

AliDeck Aluminium Decking Installation Videos

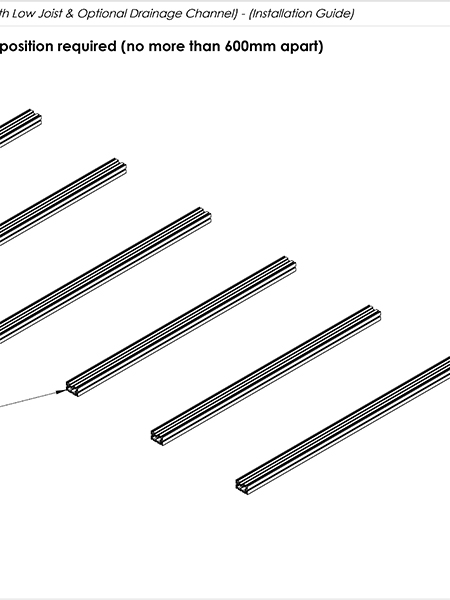

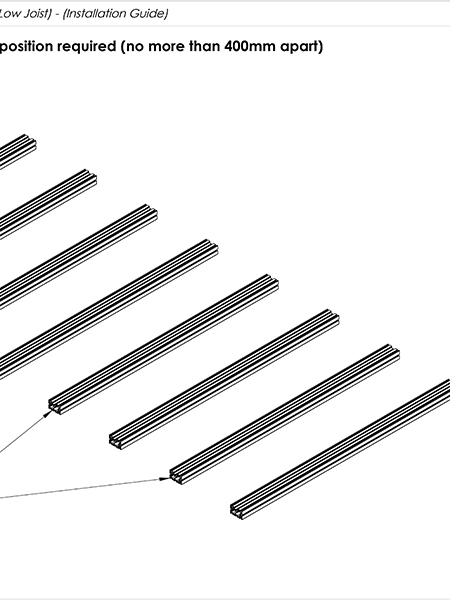

Senior Decking Board, Low Joist, Adjustable Pedestal Brackets, and Balcony Drainage System

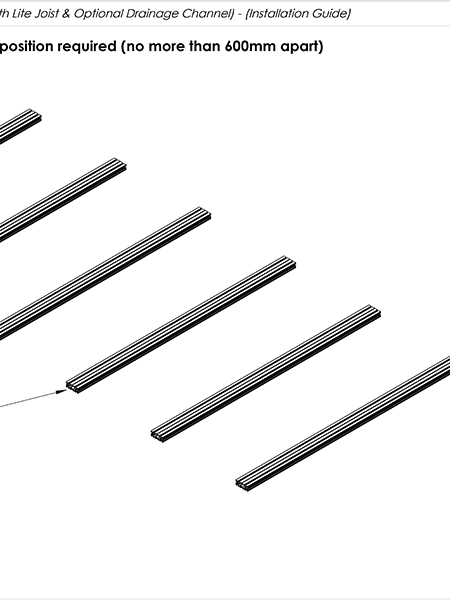

Senior Decking Board, Low Joist, and Adjustable Pedestal Brackets

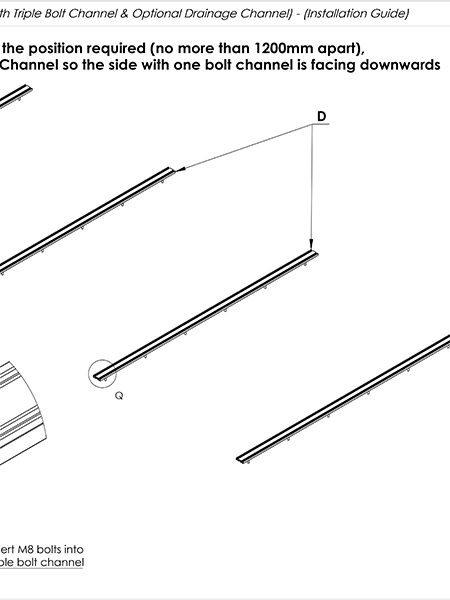

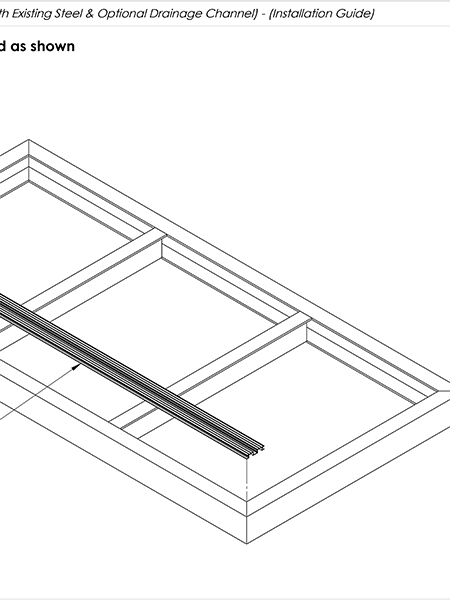

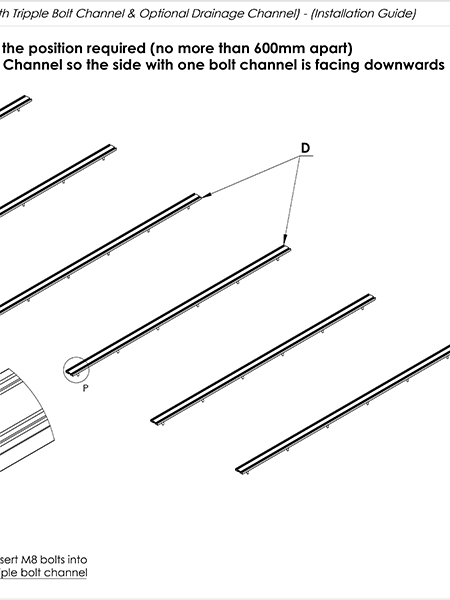

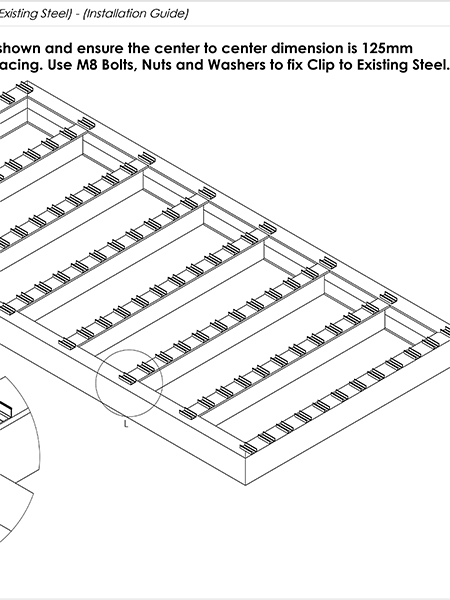

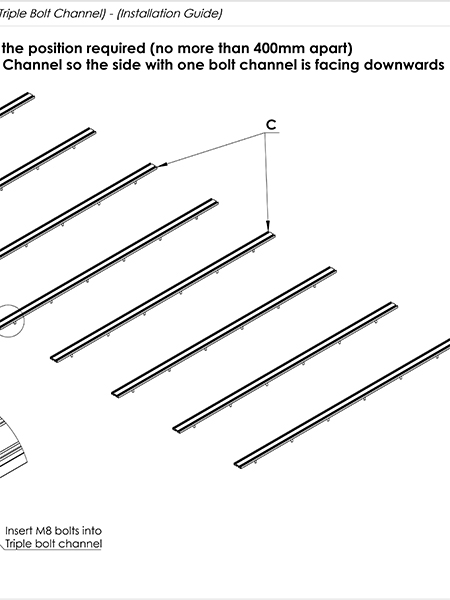

Installing AliDeck to Steel Framework using Triple Bolt Channel

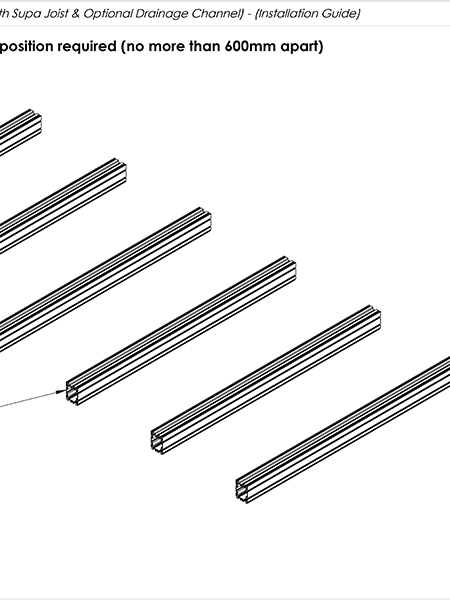

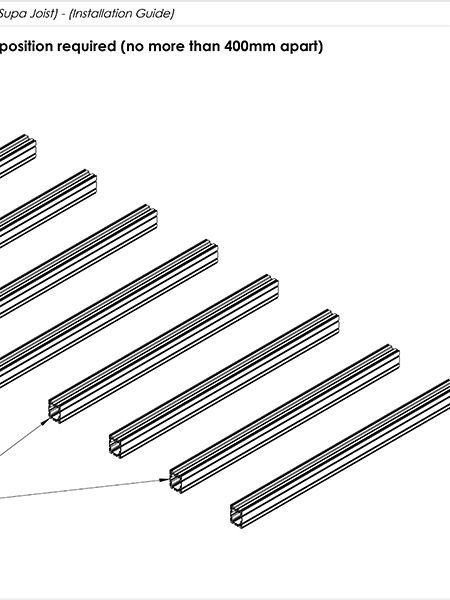

Using AliDeck Supa Joist to build elevated platform and steps

Timber Terrace Deck Replacement to Resolve EWS1 Failure

AliClad Soffit Cladding Installation Videos

AliRail Balcony Balustrade Installation Videos

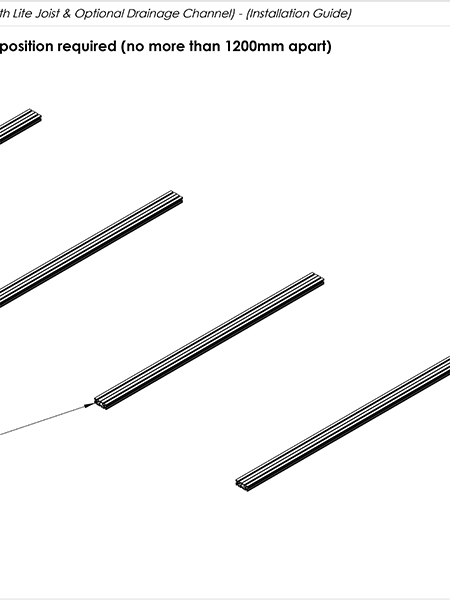

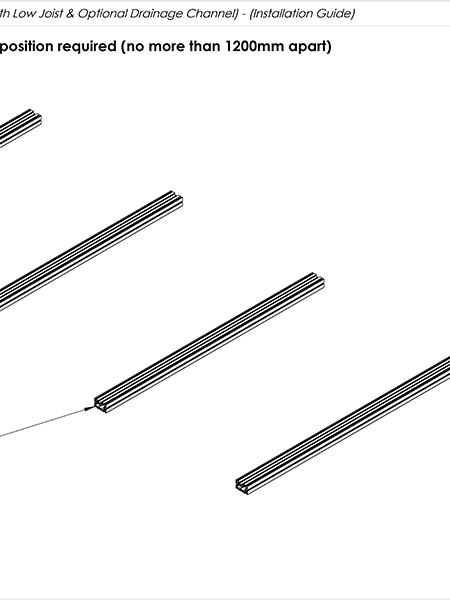

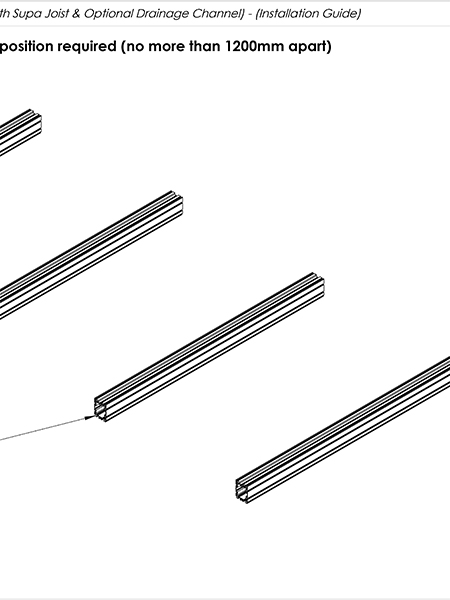

AliDeck “How To” Drawings

Maintenance Schedule

AliDeck aluminium decking requires minimal maintenance due to the natural rust resistance that aluminium features along with the high durability of our Qualicoat powder-coating. Download our maintenance schedule for instructions for maintaining the aluminium decking boards to uphold the warranty and the expected lifespan of the decking.

Time & Motion Installation Study