AliDeck’s Wind Uplift Guide

Managing Wind Uplift on Balconies & Terraces: AliDeck’s Comprehensive Guide

Understanding Wind Uplift

Wind uplift is a critical safety consideration when high winds meet vertical building surfaces, particularly affecting balconies and terraces. This phenomenon demands special attention for buildings over six stories, structures exceeding 50m height, coastal locations, and urban areas with wind tunnelling effects.

Key Physical and Design Factors:

Traditional Material Limitations:

Aluminium Decking Solutions

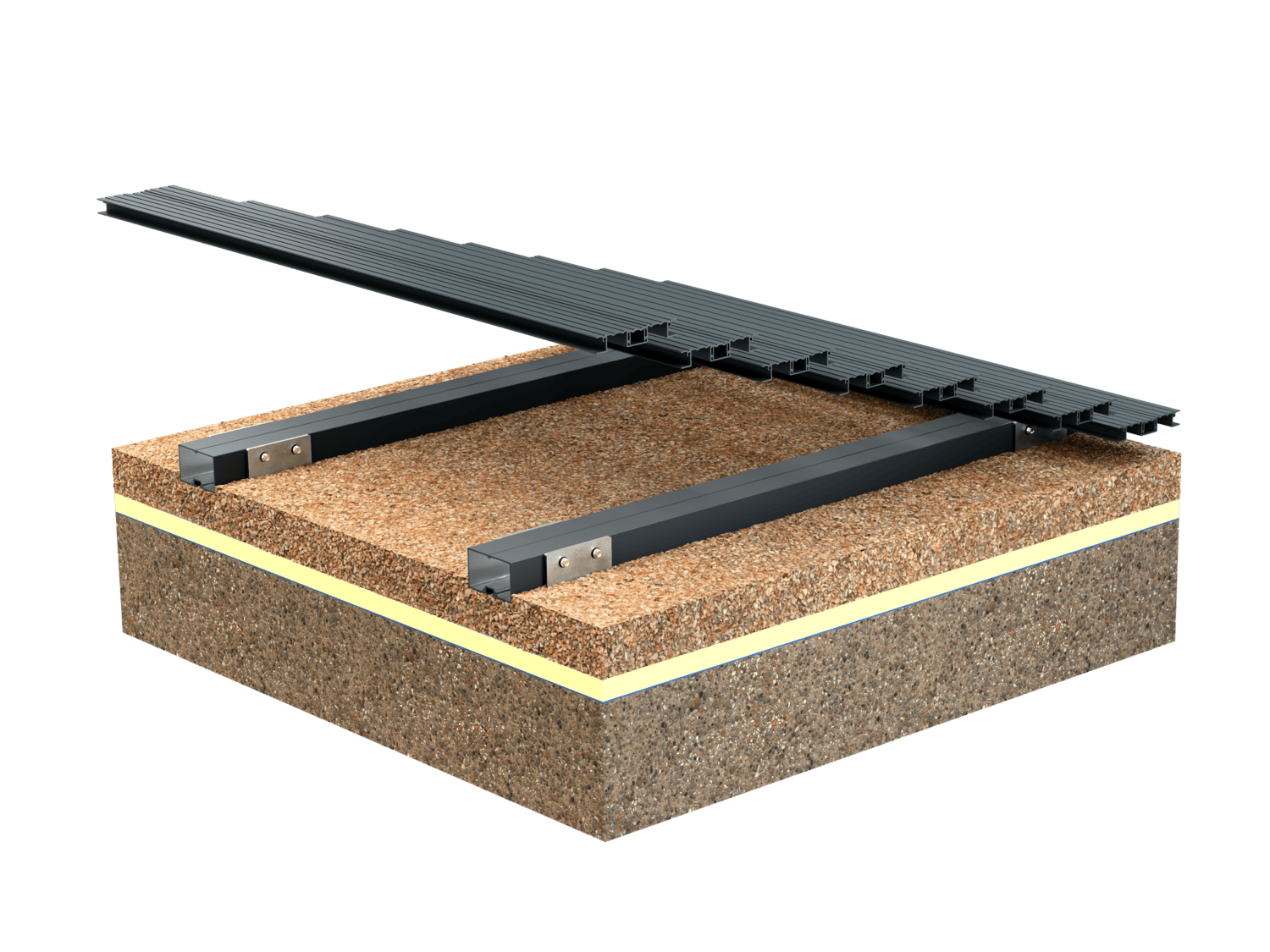

Aluminium decking systems combine lightweight properties with structural robustness, offering superior span capabilities while reducing building load. These systems feature essential safety elements including non-combustible A2-s1 d0 rating, integrated drainage, and specialised wind uplift resistant fixing methods, while providing long-term value through their 60-year life expectancy and minimal maintenance requirements, typically backed by 30-year manufacturer warranties.

Advantages of Aluminium Decking Systems

Structural Performance

Aluminium decking combines exceptional strength with minimal weight, offering superior span capabilities while reducing the overall load on buildings. The precision-engineered design ensures optimal load distribution and consistent performance across all installations.

Safety Features

Every component is engineered with safety as a priority, featuring non-combustible A2-s1 d0 fire rating and specialised wind uplift resistant fixing systems. The integrated drainage solutions and slip-resistant surface options provide additional safety measures for all weather conditions.

Installation Benefits

The quick-fit system significantly reduces installation time while maintaining flexibility for on-site adjustments and various building configurations. Precision-engineered components ensure proper fit and alignment, allowing for efficient installation across different project requirements.

Long-Term Value

With a service life exceeding 60 years and comprehensive 30-year manufacturer warranties, aluminium decking provides exceptional long-term value. The material’s inherent resistance to weather and corrosion, combined with minimal maintenance requirements, ensures lasting performance with reduced lifecycle costs.

Technical Solutions for Wind Uplift

Industry Standards and Requirements

BS 8579:2020 Guidance for Wind Uplift Mitigation:

Contact our technical team at 01622 235 672 or email info@alideck.co.uk today to discuss your specific project and wind uplift requirements.

Environmental Performance

Material Durability

The aluminium system remains stable in temperature extremes without warping or twisting, featuring corrosion resistance and UV-stable powder coating options. Manufactured from 100% recyclable materials with minimum 67% recycled content, these systems support sustainability through longevity and local UK manufacturing.

Site Assessment & Installation

Pre-Installation Evaluation

Professional site assessment includes specific wind load calculations based on building height, with detailed analysis required for buildings over six storeys and wind tunnel testing for structures exceeding 50m. Local wind patterns and surrounding building effects must be thoroughly evaluated.

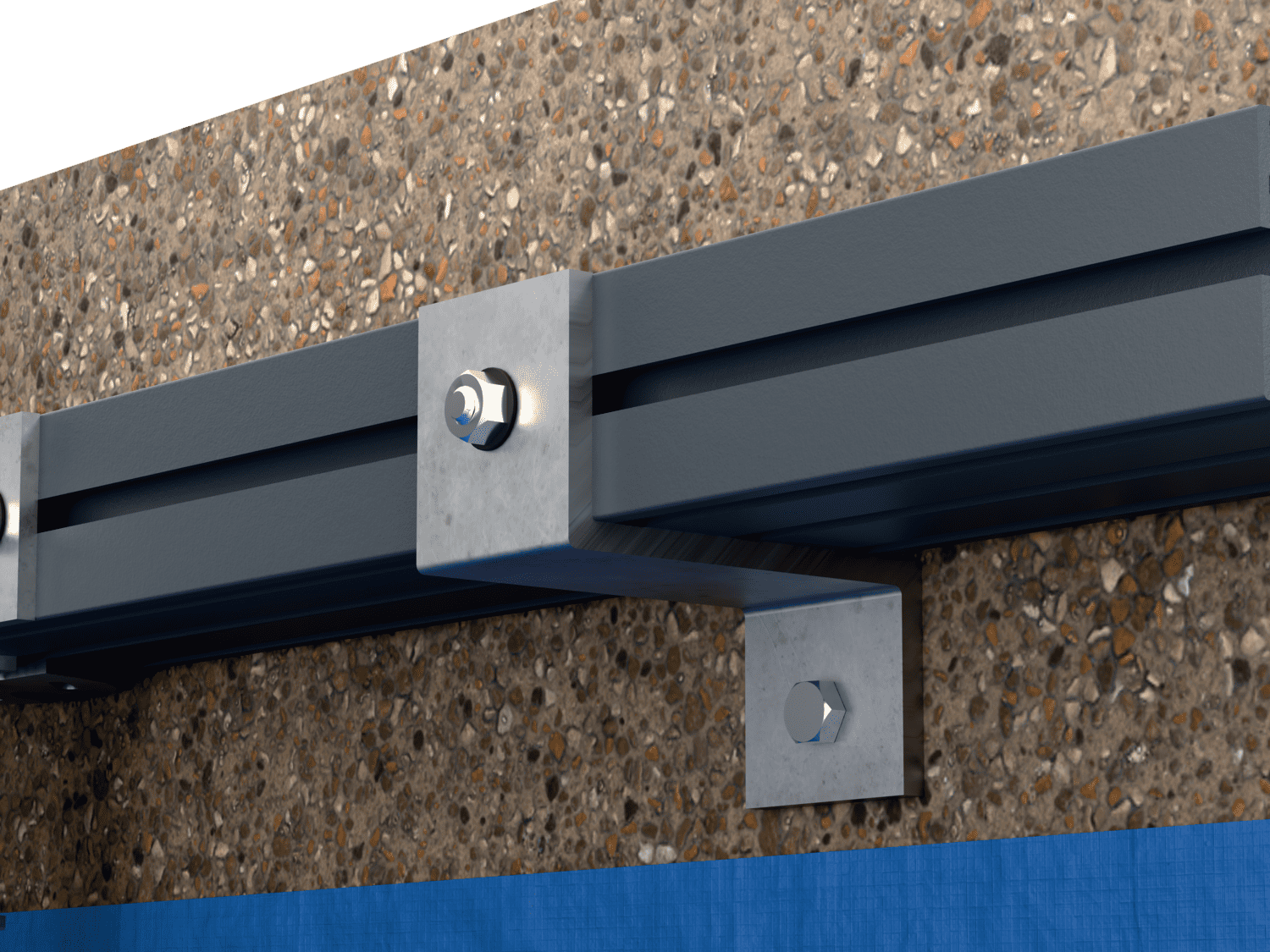

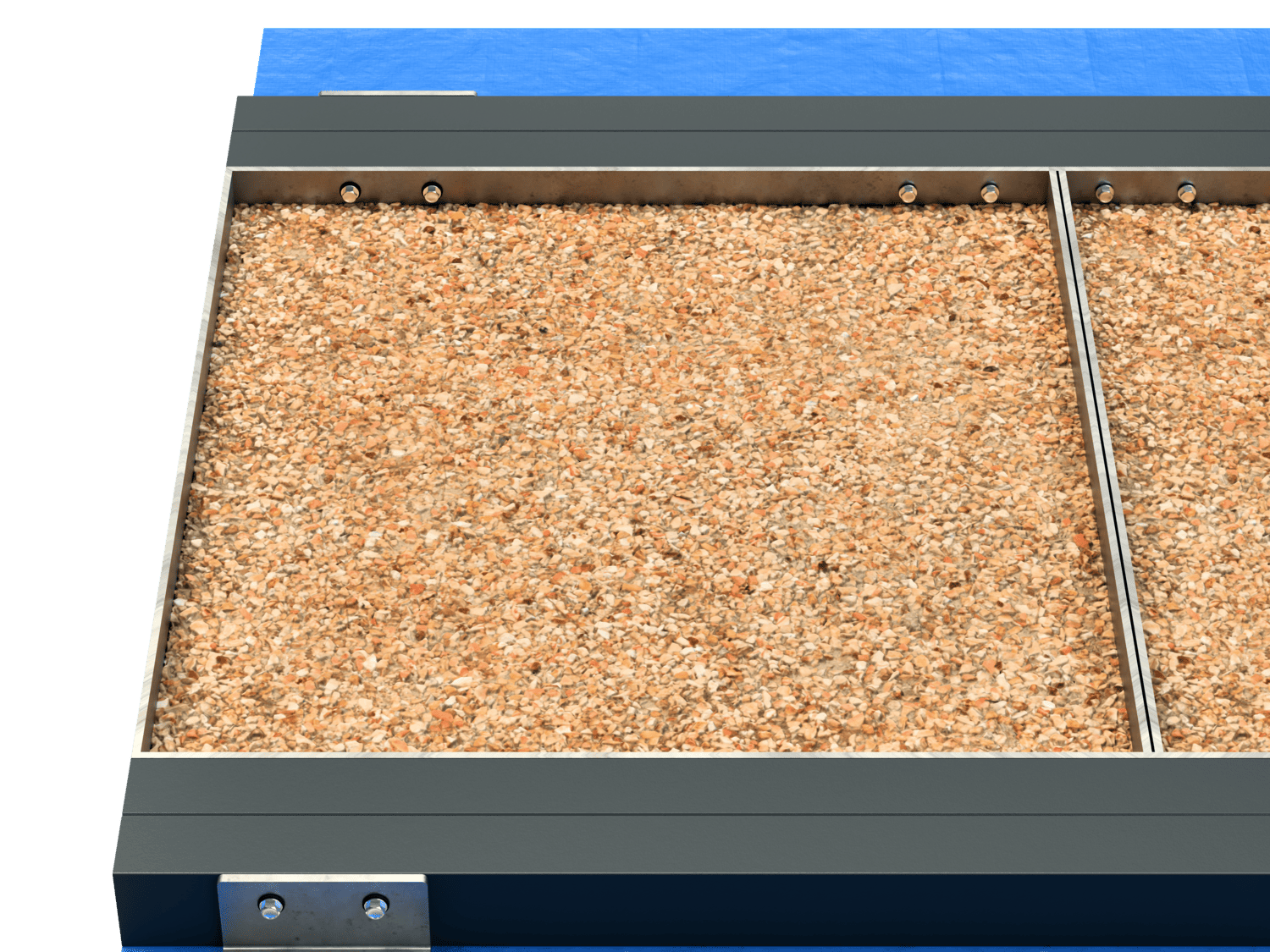

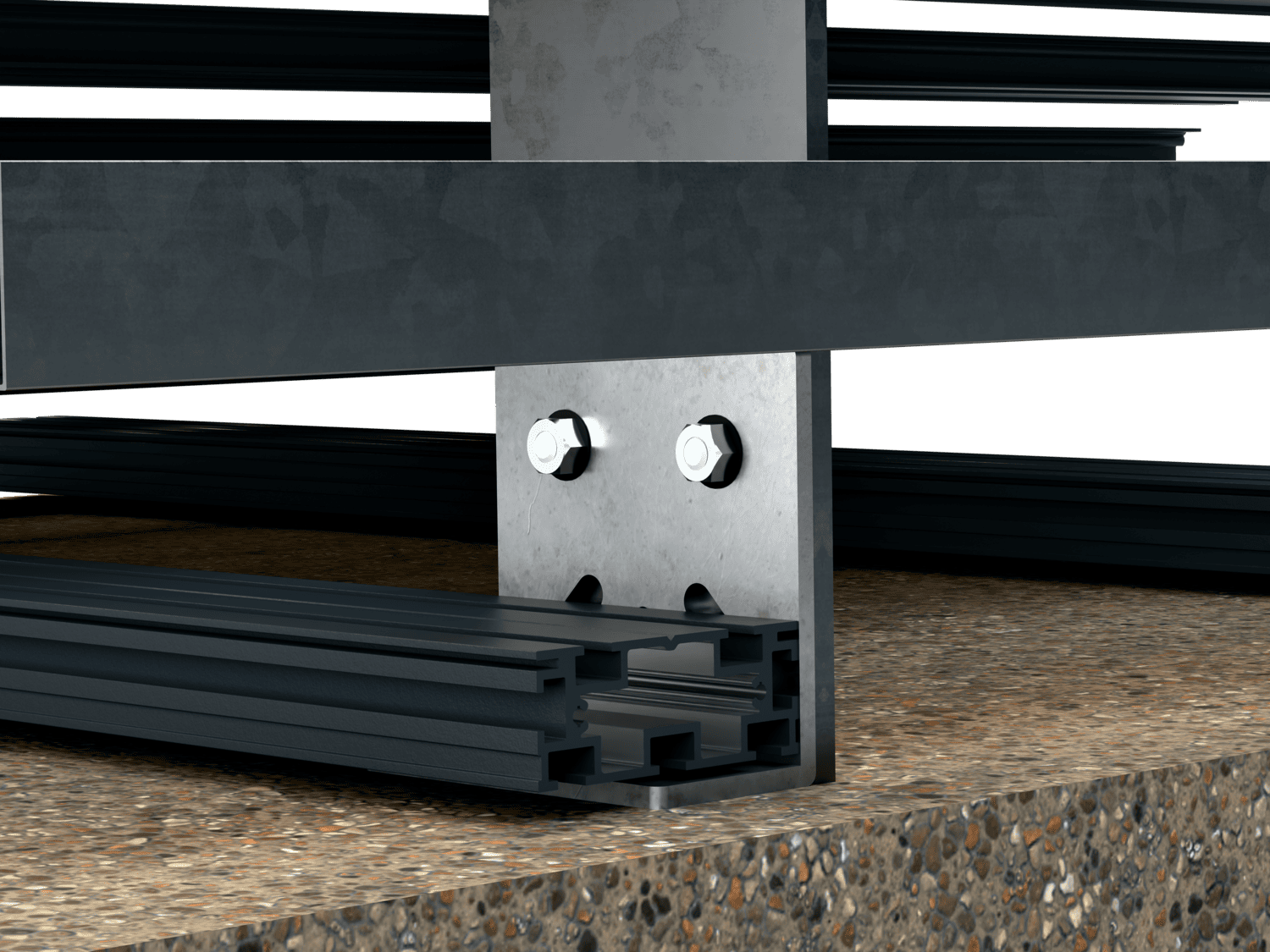

System Selection & Installation

Selection criteria include board span requirements, support structure specifications, and fixing methods based on height and exposure. Installation requires precise attention to substrate preparation, fixing spacing, gap allowances, and proper torque settings, with additional securing methods for exposed locations.

Maintenance & Compliance

Regular Maintenance

Annual structural inspections should verify fixing points, assess surface conditions, and clear drainage systems, with additional checks following extreme weather. The system requires only simple cleaning with no specialist treatments, offering easy repair options if needed.

Regulatory Standards

Systems must comply with BS 8579:2020, current Building Regulations, fire safety standards, and height-specific regulations. Professional certification includes installation training, warranty documentation, and wind load compliance certification.

Professional Support

Technical Assistance

Expert support is available throughout the project lifecycle, including:

- Technical drawings and specification support

- Site-specific wind load calculations

- Installation training and on-site technical assistance

- Custom system designs for varying environmental conditions

- Specialist solutions for high-rise installations over 50m

Note: This guide provides general information. Each project requires specific assessment and professional guidance to ensure compliance with current regulations and site-specific requirements. Projects involving buildings over six storeys, or exceeding 50m in height, require detailed wind pressure calculations and may need wind tunnel testing.